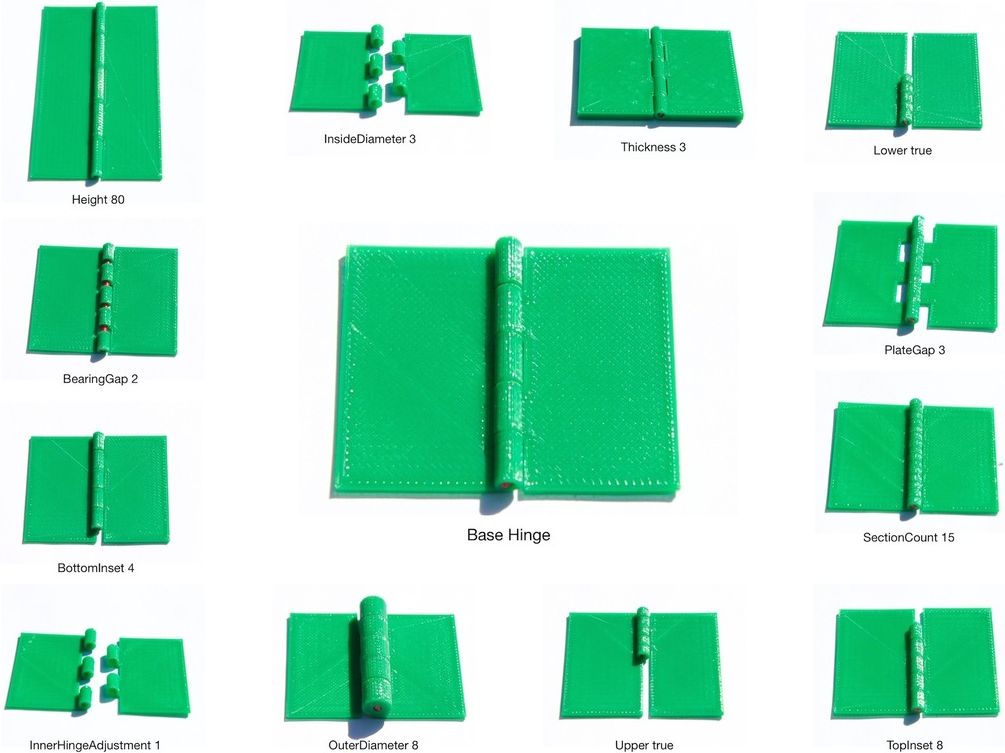

3D ontwerp SCAD – Hinge Variations

Screens:

Thingiverse commentaar:

Reusable parameterized hinges. The hinges are designed with an additive and a subtractive part, making it easy to combine with other design elements

Details

After creating the parametric pulley http://www.thingiverse.com/thing:11256 I realised this way of modelling them was only going to work for square-toothed pulleys, and a way of producing pulleys for belts with better characteristics for linear motion was required. I found dxf drawings of the relevant tooth profiles here http://oem.cadregister.com/asp/PPOW_Entry.asp?company=915217&elementID=07807803/METRIC/URETH/WV0025/F and modelled pulley diameter from data here http://www.sdp-si.com/D265/HTML/D265T016.html

There were a couple of possible approaches to importing the data, I chose to simplify the bezier curve dxf data in Inkscape, producing vertices with a resolution of around 0.05-0.1mm for each tooth. Another advantage is the the pulleys have the tooth ramp for smooth entry and exit of the belt tooth into the pulley. I’m not really sure 3D printers can take full advantage of this yet, but quality is improving all the time!

If other tooth profiles are required, or you model any, please pass them on to me and I will include them.

22 March 2012 – Updated for issue spotted by mfinn – see comments

Instructions:

The file hingePairBase.scad is the main design file. All the other SCAD files are small variations from the base and are named with the parameter they tweak. Modify the SCAD to suit.

When using the hinges, bear in mind that the hinge has a top and a bottom. Keep the plate material on the left to ensure that the subtractive parts are correctly oriented. For example, this means that if you were to lay the hinges around a polygon, one per side, you would need to make them go bottom to top in an anticlockwise direction to keep the polygon material on the left.

The pin for the hinges is filament. Try various filaments you have to find which one works best for the inside diameter you print with. I find that my glow in the dark PLA fits well in a 2.06mm inside diameter hole, but red ABS needs to be sanded down slightly. The hinge sides with the lower hingelet count are made slighly larger than those with a higher hingelet count. This is make one side grip and one side rotate smoothly.

I printed all of these in PLA at 0.2mm layer height on a Replicator 1.

Wat heb je nodig?

[#/3dprinter/model_scad/hinge_variations” ]