Ciclop onderdeel – Kogellager (16014)

3D Scanner

Ciclop

KOGELLAGER

De Ciclop 3D scanner kogelager 16014 zou oorspronkelijk gekocht moeten worden bij een winkel, deze is kan nagemaakt worden op diverse manieren om zo ook uitgeprint te worden!

Kogellager specs:

Buitendiameter: 110 mm

Binnendiameter: 70 mm

Hoogte: 13 mm

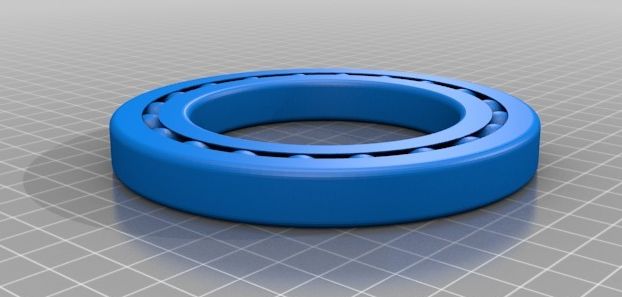

Kogellager 16014 met ballen

Wellicht een simpel model, maar best complex om te maken vooral om de ballen “los te wrikken”, ook moet deze zeer fijn geprint worden op 100 micron.

Thingiverse commentaar (ENG):

Large bearing for Ciclop 3D Scanner

I had some trouble in locating the large bearing for the ciclop in as much as I would have look for it on the internet then to leave my house to get it and it would probably cost me money. So I printed one, I figured it would take more than the time in research and effort anyway. It prints nicely but tolerance is close 0.15mm between the balls and race it released cleanly after printing and needs no supports to print. I did the plate as well I printed it in PLA the bed was a warm 50deg so it stuck like crazy I thought i was going to break it taking it off. 1st layer no fan then full fan for the rest.

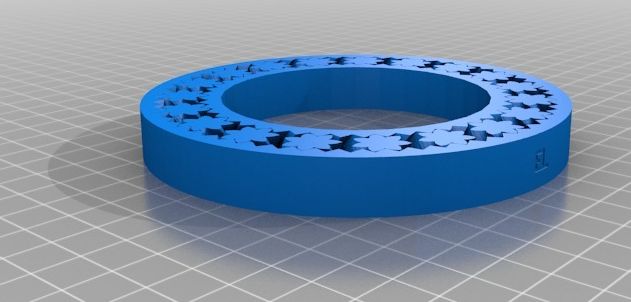

Kogellager 16014 met tandwielen

Dit is een beter ontwerp om “kant en klaar” te printen.

Thingiverse commentaar (ENG):

This is a remix of emmetts gear bearing http://www.thingiverse.com/thing:53451

It should make a nice 16014 bearing for the turn table of a Ciclop 3D scanner. 110mm OD 70mm ID and 13mm thick.

Due to the large size it can be quite tricky to get the bearing to ‘crack’ initially and get all the parts rolling. I cut two disks of wood approximately 80mm diameter and then used them to clamp the inner race in a vice. I put a wrap of double sided foam tape on the outer race to give me some grip and then pretty much thrashed, twisted, yanked and swore at it until it broke free. Not the most elegant method, but I did get there in the end.

I found once you get the bearing turning, the best way to get it running really nicely is to submerge the whole bearing in water and spin it quite a few times. As the gears wear in they make a fine plastic powder which tends to stick to the teeth and make lumps. By running it under water the fine powder gets washed away leaving you with a nice free running bearing. Once its running nicely, apply a thin film of oil in the gears before installing it.

Even with the bearing running quite nicely I found my stepper motor was still struggling to turn the platform. If you also have this problem try my geared platform:http://www.thingiverse.com/thing:1243069

Een andere methode is om de “slew bearing” toe te passen (SCAD)