3D ontwerp SCAD – Parametric pulley

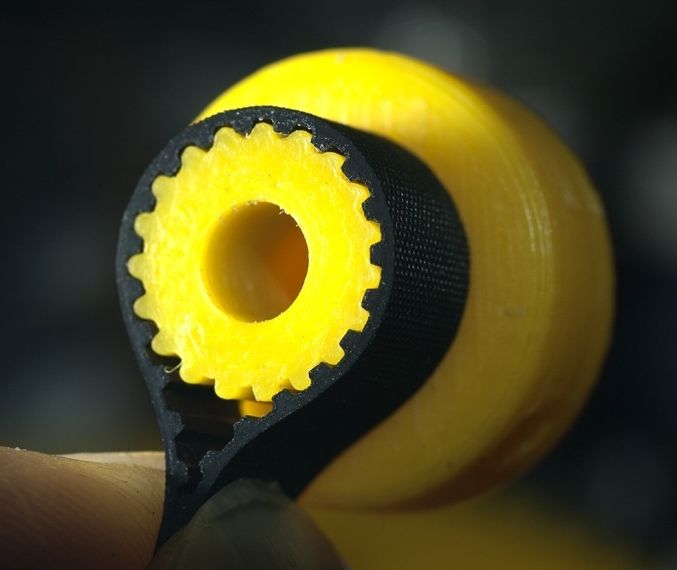

Screens:

Thingiverse commentaar:

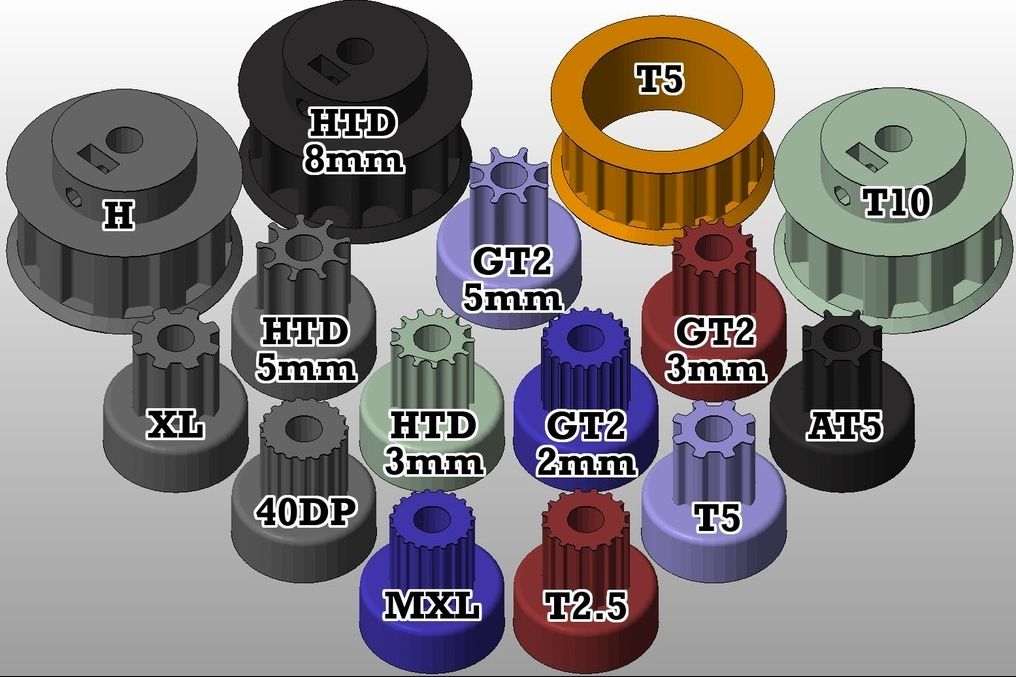

This thing will create a range of metric and imperial tooth profile pulleys, with any number of teeth, specified in the Openscad file.

Tooth profiles currently supported are MXL, 40DP, XL, L, T2.5, T5, T10, AT5, HTD (3mm, 5mm, 8mm) and GT2 (2mm, 3mm 5mm).

NOTE: error in script regarding L and H pulleys spotted by OSTycoon (see comments) – the script says H, but actually it is L profile.

There are a range of editable parameters for editing the fit of the tooth (to account for printer variation), the pulley base, captive nut(s) slot for the set screw, motor shaft diameter, pulley height and belt retainers.

The attached stls are reference pulleys, mostly around the size used on repraps.

Details

After creating the parametric pulley http://www.thingiverse.com/thing:11256 I realised this way of modelling them was only going to work for square-toothed pulleys, and a way of producing pulleys for belts with better characteristics for linear motion was required. I found dxf drawings of the relevant tooth profiles here http://oem.cadregister.com/asp/PPOW_Entry.asp?company=915217&elementID=07807803/METRIC/URETH/WV0025/F and modelled pulley diameter from data here http://www.sdp-si.com/D265/HTML/D265T016.html

There were a couple of possible approaches to importing the data, I chose to simplify the bezier curve dxf data in Inkscape, producing vertices with a resolution of around 0.05-0.1mm for each tooth. Another advantage is the the pulleys have the tooth ramp for smooth entry and exit of the belt tooth into the pulley. I’m not really sure 3D printers can take full advantage of this yet, but quality is improving all the time!

If other tooth profiles are required, or you model any, please pass them on to me and I will include them.

22 March 2012 – Updated for issue spotted by mfinn – see comments

Instructions:

- Download openscad file

- Tweak to make your perfect pulley

- Print

3.1 If you get blobs and/or stringing, you may need to reduce the perimeter speed, perhaps as low as 10mm/s depending on your electronics/baud rate etc. The model is high resolution, and slicing software will produce lots of very short moves, that the comms may not be able to keep up with. Alternatively, print from SD card. Printing slow should improve the tooth shape, and fit of the belt. - Rejoice!

Wat heb je nodig?

[#/3dprinter/model_scad/parametric_pulley” ]