3D Printer – Extruder – Greg’s Wade’s Geared Extruder

Deze pagina verteld een stukje history over het meest gebruikte solo extruder systeem: Greg’s Wade’s Geared Extruder.

Kort overzicht:

| Generatie: | Naam: | Datum: | Tandwielverhouding: | Onderdelen: |

|---|---|---|---|---|

| 1e | Greg's Wade's Geared Extruder | 2010-02 | 11/39 | 4 |

| 2e | Greg's Accessible Wade's Extruder | 2011-02 | 10/43 | 4 |

| 3e | Greg's Hinged Accessible Extruder | 2011-05 | 10/43 | 4 |

| 4e | Greg's Guidler | 2012-02 | 10/43 | 5 |

| 5e | Greg's Wade reloaded | 2012-03 | 9/47 | 5 |

| 6e | Diverse | 2012-03 - 2015-08 | 9/47 | 5 |

| 7e | Ultimate Greg's Wade's Geared Extruder | 2015-08 | 9/47 | 5 |

1e generatie (Feb 2010) – Wade’s original design

Informatie (ENG):

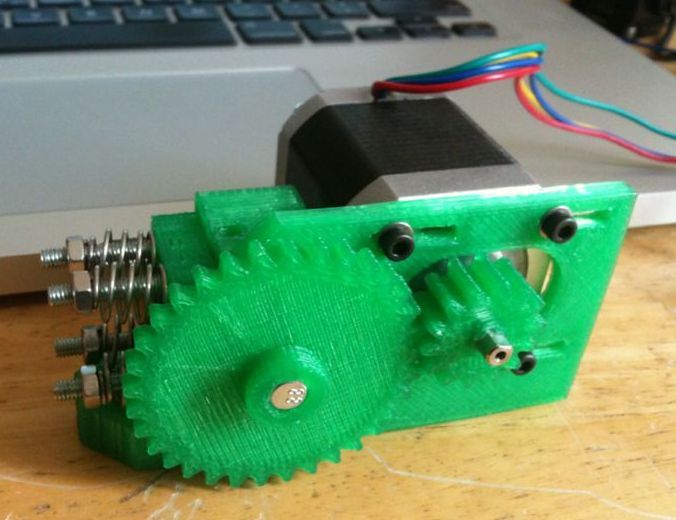

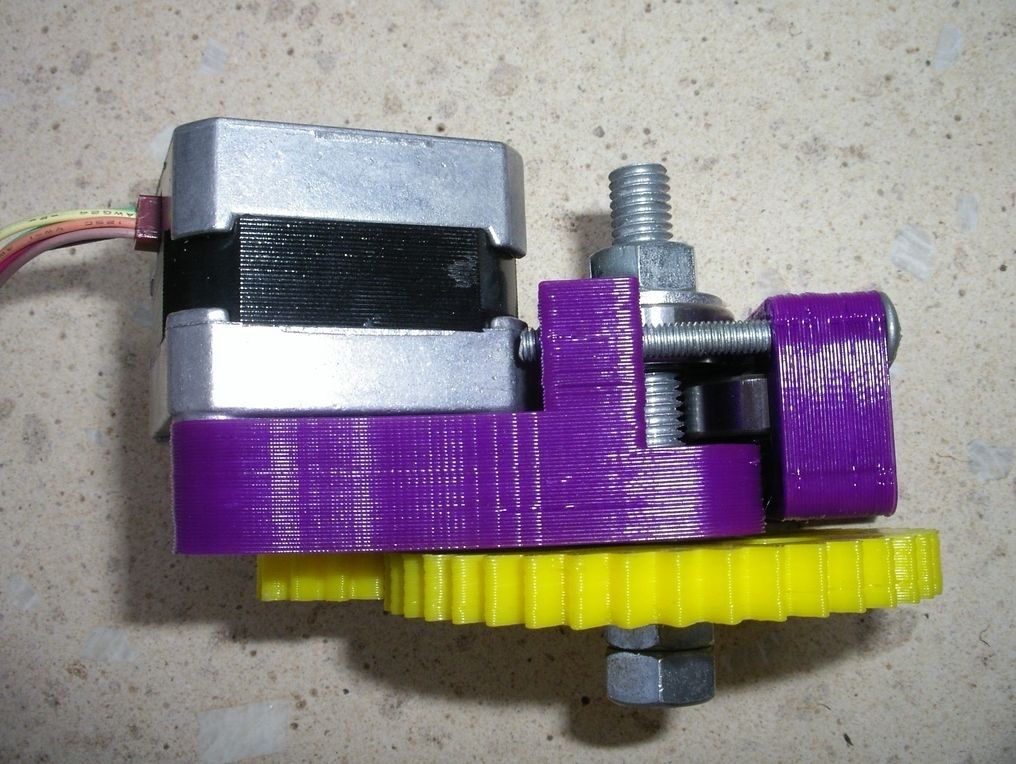

The original Wade’s geared extruder from February 2010 is itself an evolution of an earlier extruder design by Adrian Bowyer and also includes many ideas from Nophead’s early research on extruders. Wade apparently used Alibre, a proprietary CAD program for Windows, to design his geared extruder.

All the files for this early extruder design are still available both here on RepRap.org and also on Thingiverse. One should note that as much as it has been improved upon by later derivative designs (see below), the basic features of this extruder remain exactly the same, five years later: a NEMA 17 stepper motor driving a small gear that drives a big gear whose axle is a hobbed bolt that pushes our filament, with compression provided by a spring-loaded bearing.

Thingiverse commentaar (ENG):

This is a new extruder design based on Adrian’s geared nema 14 extruder, with some ideas from Nophead\’s extruders. During testing it produced over 16 kg of pulling force on the filament. Hot end development is still ongoing, but it should plug and play with any existing 16 mm thermal breaks.

Download @ RepRap.org

Download @ Thingiverse

2e generatie (Feb 2011) – Greg’s Accessible Wade’s Extruder

Informatie (ENG):

This was published on Thingiverse in February 2011 i.e. about a year after the publication of the original Wade’s extruder. Greg redesigned Wade’s extruder from scratch using OpenSCAD, a move that imo allowed the design’s evolution to really take off.

Thingiverse commentaar (ENG):

This is an extruder based strongly on the wades from the Prusa git repo. It has several features over the standard wade:

- Accessible hobbing. If you strip the filament, there is no need to disassemble in any way (such as removing the idler/filament or bolt) in order to remove the stripped plastic from the hobbing. You can get a needle in the hole in the top and scrape it out.

- The motor can be removed without removing the large gear. The three mounting screws can be accessed without removing the gear. 2 of them are clearly accessible and the other is accessible through a hole in the gear.

- Slightly higher gear ratio than standard wade. This design uses 43:10 instead of 37:11.

- The rotated motor mount means that the carriage attachment screw is accessible with the motor installed.

- The rotated motor mount also means that the clearance past the idler attachment captive nuts is a bit longer, so you have a bit more play tensioning the idler.

- The motor is far enough back from the face that the small gear can be mounted with the hub towards the motor (necessary with short shafted motors) and it will mesh with the large gear when there is only 1 washer between the bearing and the large gear.

- The large gear has a shallow nut trap so that locking halfnuts can be used with hobbed threaded rod (infinitely adjustable hob alignment) rather than a bolt.

- The motor mount screws are recessed allowing the large gear to be almost against the face of the extruder body.

- It has sexy curves.

The OpenSCAD source includes references to Josef Prusa’s GitHub repository so I imagine the extruder was designed to be used with the Prusa Mendel, at the time the “current” Prusa design.

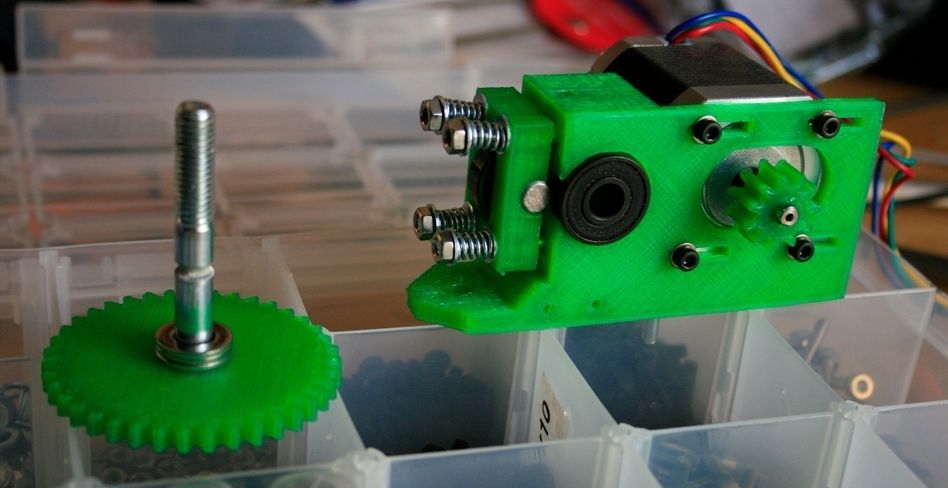

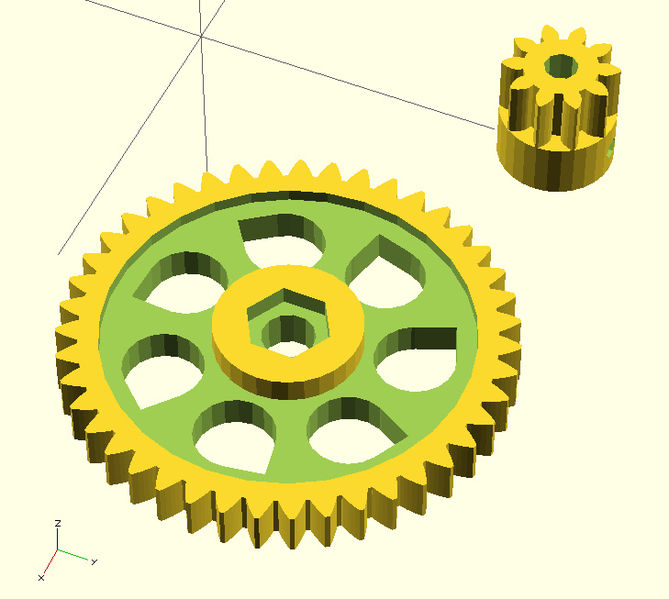

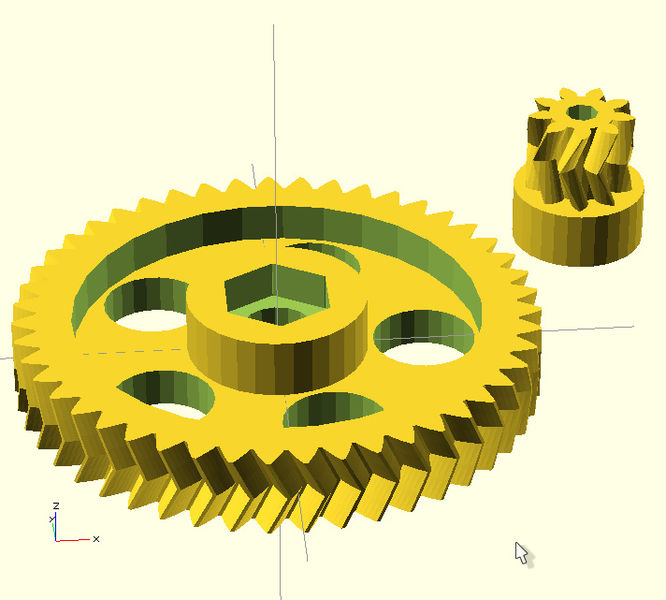

Together with his extruder body design, Greg also published a nice set of gears (gear ratio 10:43), using his own OpenSCAD gear library:

About a month later Greg published version 2 of his extruder, which is pictured below:

Generate STLs from the version 2 scad to get the version 2 changes.

NOTE: To do this you must have configuration.scad from the prusa git repo in the same directory as gregs-wade-v2.scad so that bolt and nut sizes defined in that file can be used.

Version 2 Changes:

- Added the 4th idler screw hole.

- Moved the top captive nuts for the idler screws closer to the idler so that you can screw the idler bolts in further

- Made the motor mount slots go a further 1mm away from the hobbed bolt (as requested by spacexula)

- Added the framework for hotend mount supports (I still need people to tell me what their particular hotend mounting needs are). Each hotend defines its holes assuming that the extruder block is sitting vertical with the filament exit hole at [0,0,0]).

3e generatie (Mei 2011) – Greg’s Accessible Wade’s Extruder

Informatie (ENG):

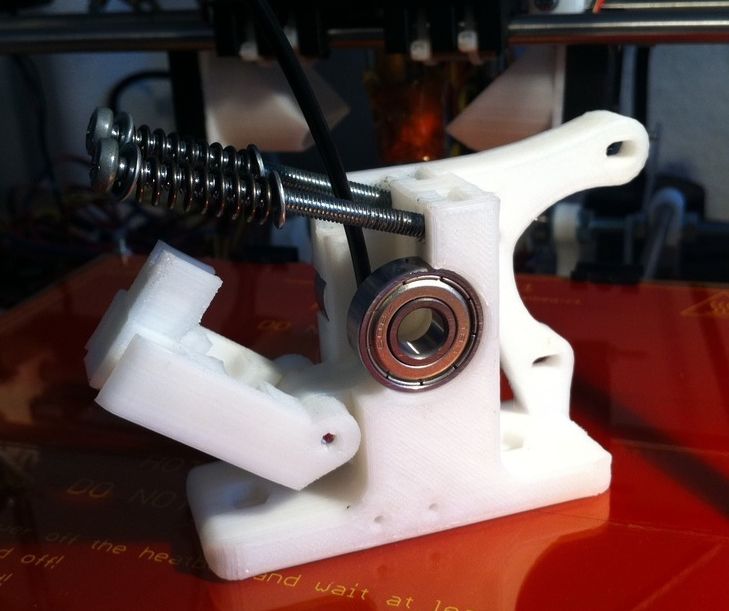

Greg published the third version of his extruder on Thingiverse in May 2011, about two months after the publication of version 2. The main improvement is of course the addition of a hinged idler, as the name of the thing indicates.

This is how Greg describes his improvements:

This is an update to my Accessible Wade’s Extruder.

The idler is now hinged using an M3 screw.

I have also added support for the central part of the 608 idler so that there is no need to use washers to space the bearing away from the plastic.

I have been using this design for a while now and love it.

Changing filament is a simple as compressing the spring then whipping out the old filament and poking the new one in.

Instructions:

The hotend mounting configuration can be selected in the openscad file.

simply call the wade module like this (which is how the included stl was made):

wade(hotend_mount=mendel_parts_v6_mount);

If two mounts have compatible holes, you can include the holes for both like this:

wade(hotend_mount=mendel_parts_v6_mount+peek_reprapsource_mount);

Once it is printed, you will need to trim off the little support piece for the idler hinge and drill the support membranes from the hobbed bolt hole and motor mount holes.

4e generatie (Feb 2012) – Greg’s Guidler

Informatie (ENG):

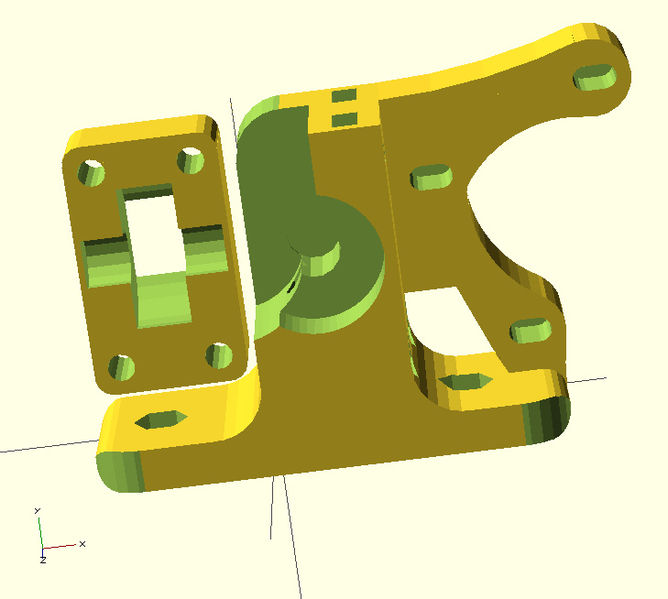

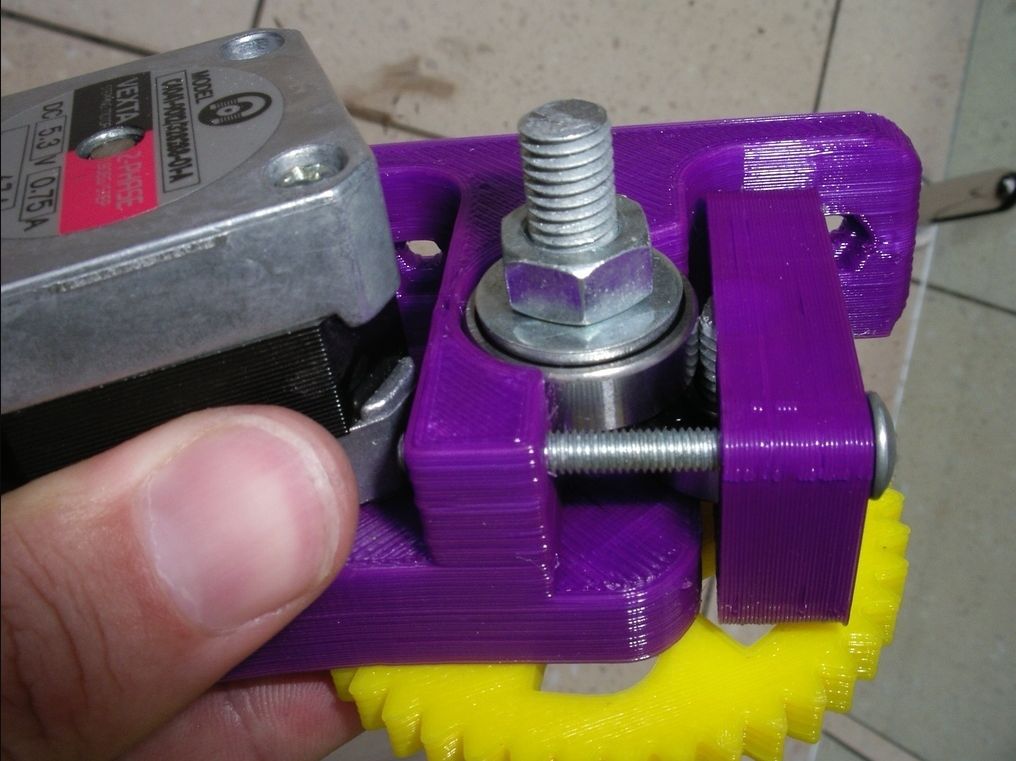

In February 2012 Greg came up with a 4th version of his extruder design, published on Thingiverse as “Guidler for a Gregs Wade”, although the newly published thing was really a complete extruder.

Now, why did Greg use the previously unheard of word “guidler”? In Greg’s own words:

I have incorporated a filament guide on the idler (and coined the term guidler).

I also took his modification so the front bearing doesnt rub and I have included a printed spacer so the bottom bearing doesnt rub either (just insert it before the bearing).

I also widened the opening a bit for better access to the hobbing (another of Tom’s ideas).

I also included one of Triffid Hunter’s suggestions to modify the hinge support piece slightly to make it easier to remove.

Thanks Tom and Triffid for the ideas.

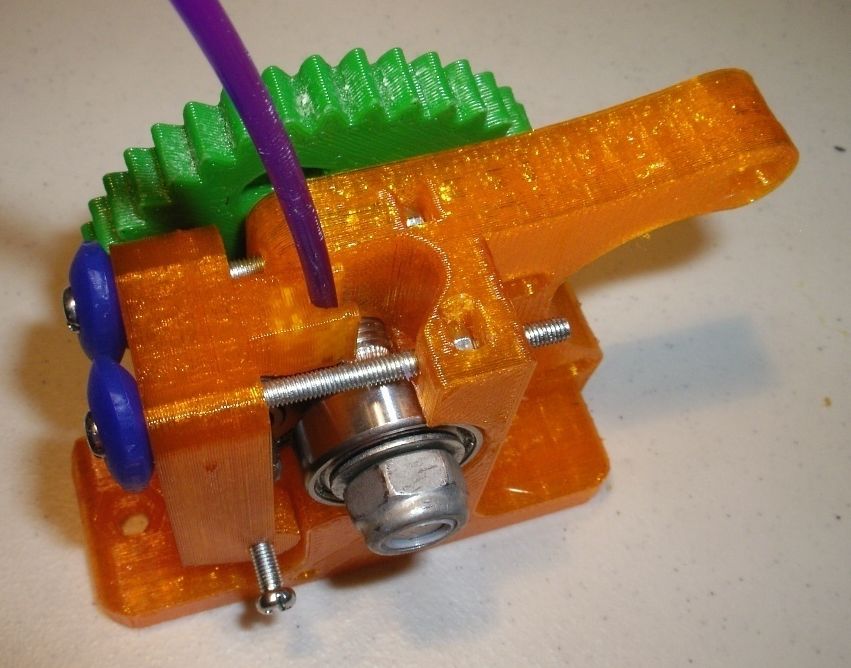

5e generatie (Mar 2012) – Greg’s Wade reloaded

Informatie (ENG):

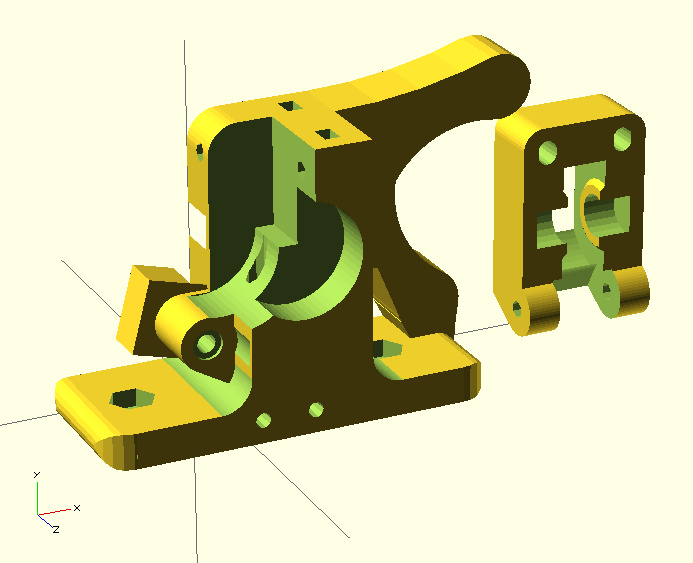

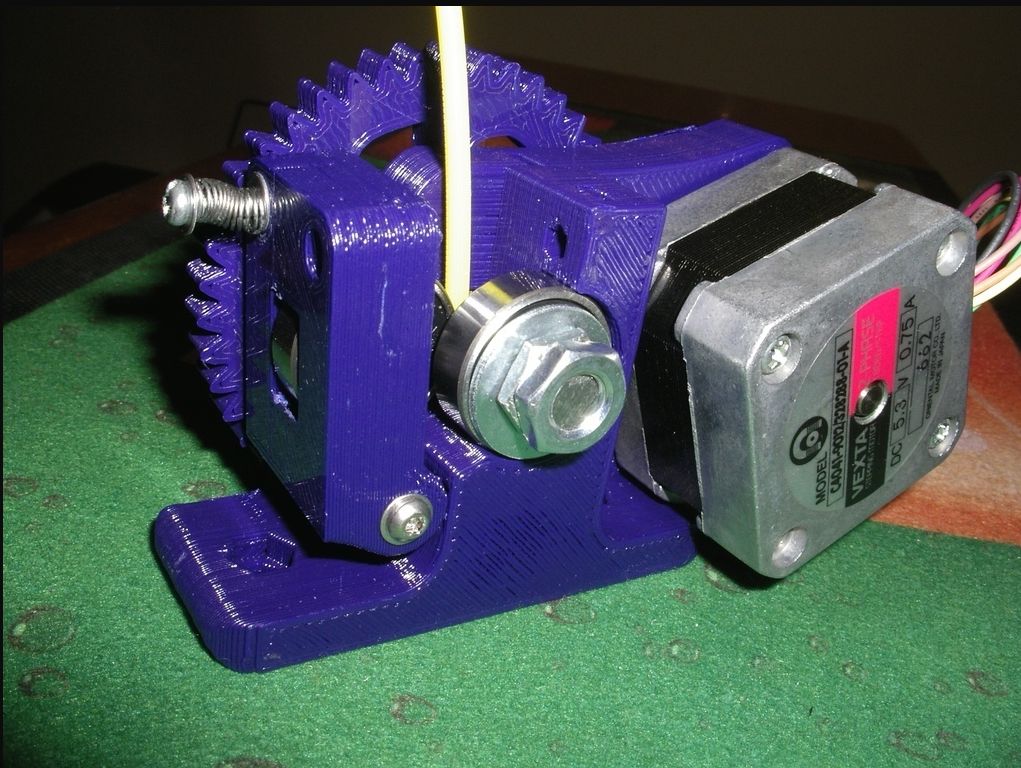

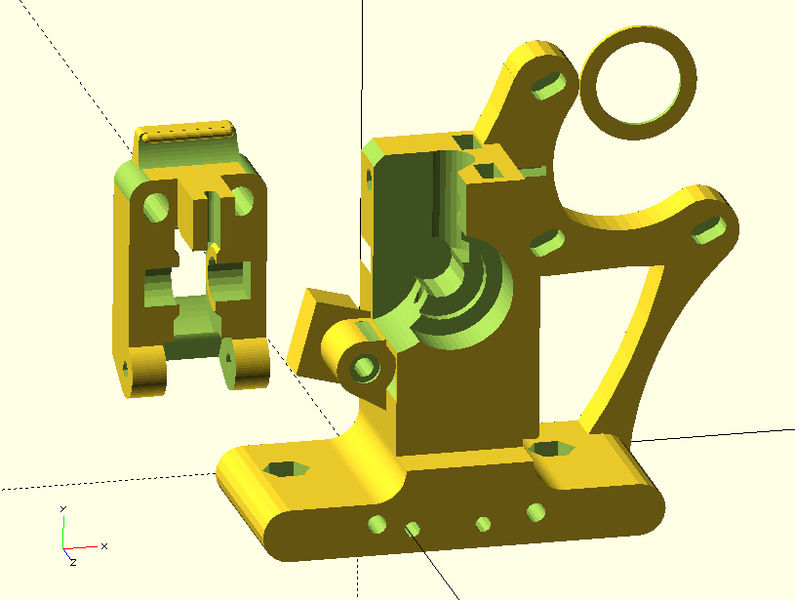

In March 2012, just one month after Greg had published version 4 of his extruder, Jonas Kuehling published his “reloaded” version of Greg’s Wade’s Geared Extruder on Thingiverse.

The list of improvements/modifications is quite extensive:

This derivative of Greg’s Wade Extruder collects all the best ideas and latest features and improvements:

- Greg’s excellent “Guidler” for perfectly lined up filament feed AND easy access of the hobbed bolt

- Tiltable idler-screws for opening the idler without removing the screws entirely

- 4mm elevation of whole extruder body/bolt/motor mount to allow slightly bigger 9/47 herringbone gears

- 2mm extra bolt-motor-distance for the same reason

- M4 nuts and screws for idler, since M3 screws in more than 60mm length are sometimes hard to source (at least in the common hardware stores of northern germany..)

- Well, 9/47 herringbone gears!

- All nut-traps have been corrected for correct fit (all prusa parts seem to use slightly wrong sizes.. should be 5.5mm wrench size for M3 nuts, I changed all of them to the right ISO values with additional 0.2mm clearance. Fits great for a precisely calibrated prusa)

- Additional hotend-mount option “reprapfaborg” for Stoffel15’s great hotends that use 10mm shaft diameter of 20mm length (shown on one of the pictures as a cut-view); you can get one via http://reprap-fab.org

- 8mm thickness of motor mount (instead of 10mm) in reference to wider herringbone gear

I made STL-exports for these three hotend-mounts:

- groovemount

- jhead mount

- reprap-fab.org

My configurations were made for 0.25mm layerheight (using 0.35mm nozzle), so if you’re using larger values please change the parameter in the SCAD and export your own STL. Otherwise the support-layers of bearing-hole and idler mount may not be sliced correctly.

UPDATE 2012-03-12:

– As Zarquon requested via comments, I uploaded a SAE compatible version of the groovemount-extruder-body as well as the big gear. Actually I simply replaced the parameters for M3/M4/M8 nuts to the values Zarquon submitted. Please leave a comment if something still doesn’t fit.

UPDATE 2012-03-16:

– Added gear-sided nut traps for GRRF hotend mount in the main wade SCAD file

– Uploaded additional small gear STL for 4.2mm center hole diameter as requested by pharaohabq in the comments

UPDATE 2012-03-26:

– Added new parameter “less_idler_bolt_dist” to adjust distance between idler and hobbed bolt, in case the idler isn’t exactly vertical when tightened but slightly angled towards to hobbed bolt, which could cause the spring loaded screw to pop off the slots to the top of the idler. Default is “0”, adjust for your own requirements if neccesary.

It is quite interesting that Jonas adopted the word “guidler” just one month after Greg had coined it; my guess is the idea was so good that it needed the catchy name that Greg had given it. Another interesting fact is that Jonas’ work had so many derivatives (Jonas’ thing was remixed a grand total of 67 times!) that 3 years later it has become difficult to distinguish a single evolutionary path from that point on, as there are so many derived extruder designs that are available on the web. Another issue that clouded the evolutionary path here is that Jonas did not add his copyright to the source code, and the only way to distinguish his changes to the source code is using a diff-style program (an automated program that lists the differences between two text files).

6e generatie (2012-2015) – Diverse

In deze periode zijn er heel veel remixes gemaakt van diverse Greg’s Wade bronnen, een aantal bekenden:

Alberto Valero’s Bowden remix

The idea of using a Greg’s Wade’s Geared Extruder with a Bowden filament system dates back to November 2012, when Alberto Valero published on Thingiverse his remix of Jonas Kuehling’s Greg’s Wade’s “Reloaded” (with OpenSCAD sources, based on Jonas Kuehling’s sources)

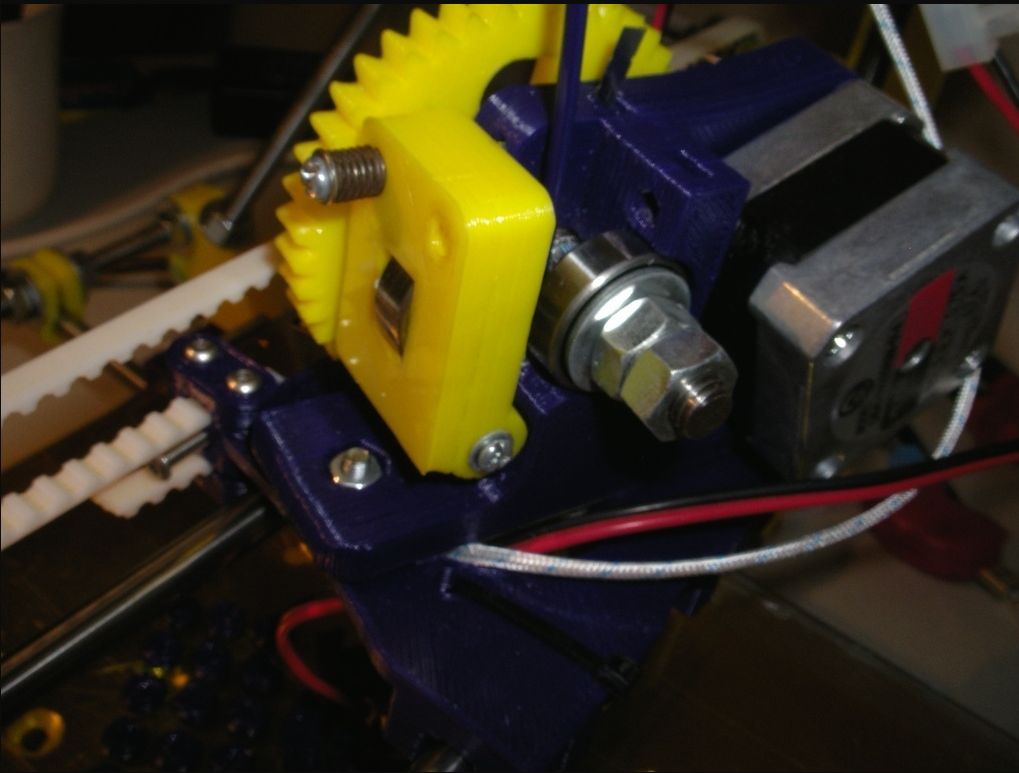

Misan’s “Bob’s your uncle” remix

Misan’s “Bob’s your uncle” version of Greg’s Wade’s Geared Extruder was published in March 2013 on Thingiverse and designed for the Prusa i3, the design of which had just been published by Josef Prusa. The Prusa i3 was the “hot new kid on the block” among 3D printer designs at the time and Misan’s “Bob’s your uncle” version of Greg’s Wade’s Geared Extruder almost immediately became extremely popular among reprappers building an i3 or even considering a build.

Misan’s version is based on Greg’s code but incorporates some of the improvements/modifications in Jonas’ “reloaded” version. Also he is using the exact same fishbone gears as those in Jonas’ “reloaded”. There is the same issue with Misan’s published version as with Jonas’ version: he too, forgot to add his copyright or any clear indication of his changes of the source code.

Ch1t0 rotated versions of Greg’s Wade’s Geared Extruder

Published by ch1t0 (Ramon Garcia) in April 2013 on Thingiverse.

By reading the comments I have determined that ch1t0 took Greg’s design and imported it in SolidWorks (a proprietary CAD program), then made all his changes and added his own original (or not? hard to tell at this point, see the Discussion tab for details) ideas. However, ch1to never published (as far as I can tell) his SolidWorks files (but in comments he said it can send the sources by email), thus hampering further remixes of his design. In fact, by breaking the OpenSCAD design chain, ch1t0 effectively signed the death sentence for this particular “evolutionary line” of the Greg’s Wade’s Geared Extruder, as far as I am concerned. And that’s a pity, because his version is really very interesting.

The i3 Rework problematic rotated versions of Greg’s Wade’s Geared Extruder

In July 2013 eMotion-Tech, a French company based in Toulouse, published on Thingiverse the complete set of STL files for their i3 Rework version of the Prusa i3, based on earlier work on the Prusa i3 EiNSTeiN variant. Among these STL files was their derivative of Greg’s Wade’s Geared Extruder.

Whereas Misan’s version of Greg’s Wade’s Geared Extruder strives for simplicity, the i3 Rework version of Greg’s Wade’s Geared Extruder is more original in the sense that it rotates the whole body of the extruder in relation to the X-axis: the gears are now perpendicular to the X-axis. This in fact leads to a rearrangement of the various elements of the extruder but still, it retains all the features that the Greg’s Wade’s Geared Extruder is known for. Another very important innovation in the i3 Rework extruder is that the layer fan is integrated in the design, it is not an afterthought.

Now, the big problem here is that, contrarily to Misan’s work, the i3 Rework extruder design has some serious issues with its copyrights and is not compliant with the GPL:

- Source code or CAD files are missing.

- Incorrect attribution.

In fact the i3 Rework extruder is a trivial remix of the extruder published by ch1t0.

Wade L3K

Published by skarab (Sébastien Mischler) in October 2014 on GitHub.

This is a remix version of ch1t0’s STL files (with the rear base of the rework version) designed from scratch on Sketchup. The first goal for this remix is to improve the guidance of flexible filament by integrating the filament guide in the body closer to the hobbed bolt. Unlike these direct fathers it is open source but also break the OpenSCAD chain.

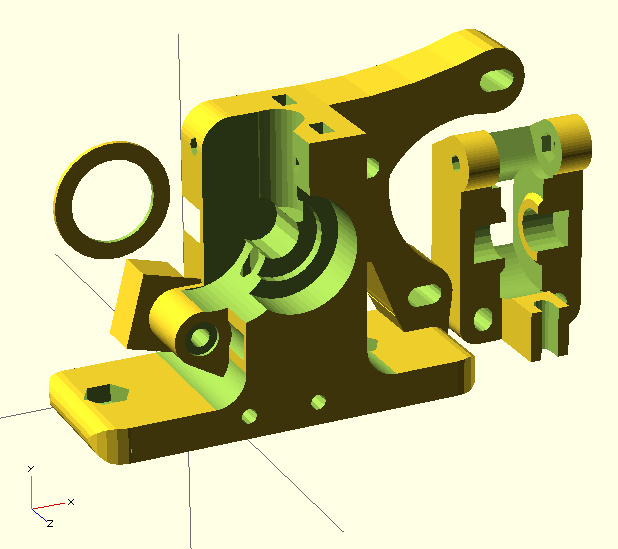

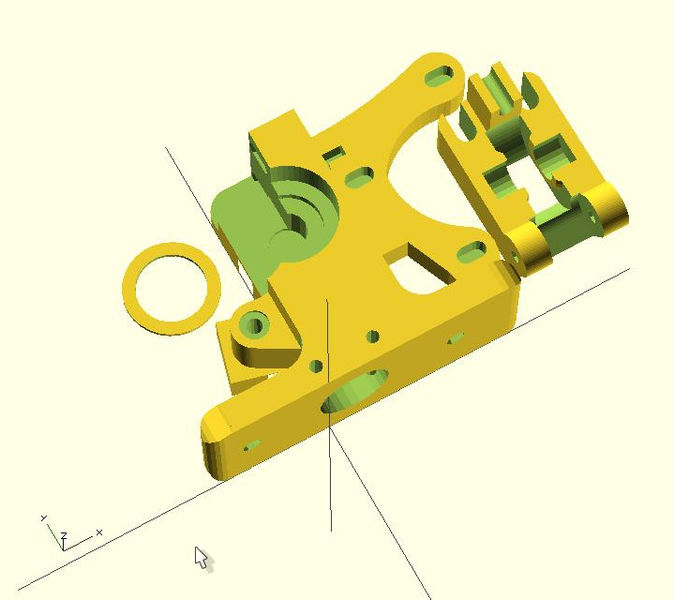

7e generatie (Aug 2015) – Ultimate Greg’s Wade’s Geared Extruder

In August 2015, AndrewBCN published on Thingiverse the Ultimate Greg’s Wade’s Geared Extruder, which is actually a small evolution of Misan’s “Bob’s your uncle” version. I have also included the OpenSCAD source code for the fishbone gears (see next section below). The idea here is to have a complete, maintained set of OpenSCAD source code files for various versions of Greg’s Wade’s Geared Extruder. In other words, a common source code base and not the dozens of separate versions that are rather impossible to maintain.

Right now the Ultimate Greg’s Wade’s Geared Extruder covers the following configurations:

- A large variety of possible hotend mounts.

- Both 24mm and 30mm spaced X-carriages are supported.

- Both 1.75mm and 3.00mm filament diameter versions are supported.

- Gear ratio is configurable.

- Various tolerances and dimensions can be configured.

- A Bowden version is available with the option of a mounting bracket or just the normal base. See Ultimate Greg’s Wade’s Geared Extruder – Bowden version

The planned evolution of this design includes adding a version with Prusa i3 Rework mounting (hence fixing the basic issue of lack of source code and proper licensing examined above).

Additionally, a complete, integrated layer fan system is available as an add-on for the Ultimate Greg’s Wade’s Geared Extruder, see Configurable 40mm fan duct / mount for Wade’s extruder for details.

[#/3dprinter/extruder/gregs_wades_geared_extruder” ]