Prusa i3 Rework – Informatie en onderdelen

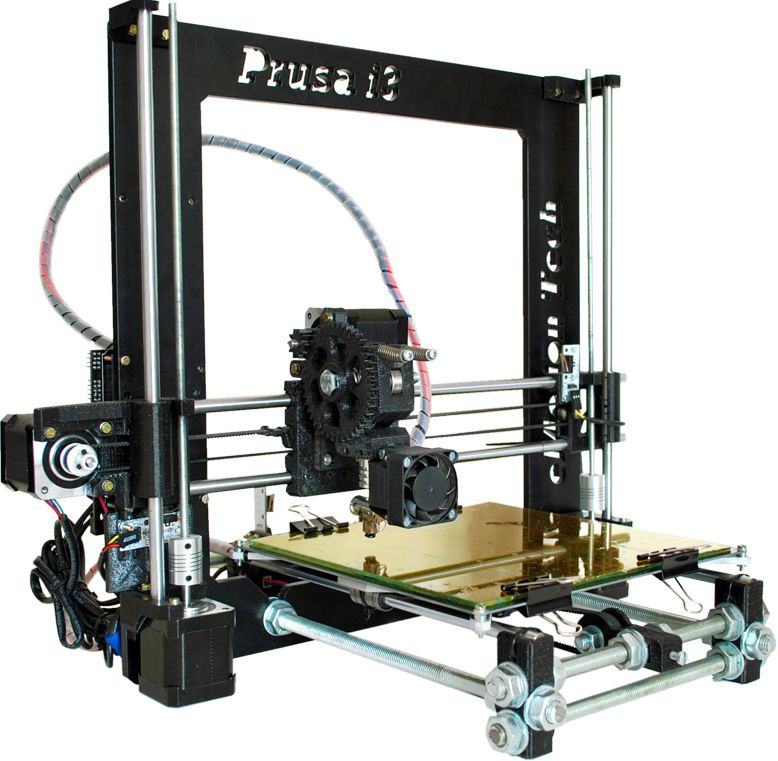

3D Printer

Prusa i3 Rework

Informatie (ENG):

This version of the Prusa Mendel iteration 3 rev 1.0 is based on the EiNSTeiN VARIANT (M10 threaded rods instead of M8).

Changelog:

04/11/2013 : 1.75mm extruder version added

We changed some features:

- Extruder upgrade :support J-Head

- New cooling fan duct for J-Head

- Y Idler with a tensioner system.

- X End Idler with endstop holder.

- Upgrade X End Idler in order to support 624 bearing.

- Y Motor with endstop holder.

- Addition of Z Endstop Holder in situ.

Enjoy !

The Prusa i3 Rework evolve in revision 1.5 !!

eMotion Tech realized several improvements:

- A new extruder with the following features :

— 1.75 mm filament compatible

— light, ergonomic and compact

— inductive auto-leveling probe

— automatic print cooling - Leadscrew Z (diameter 8mm / pitch 2mm) axis insuring faster and accurate movements

- Relocating the X and Y axis endstops to simplify the wiring

- Modification of the « Z top Left » and « Z top Right » for more rigidity

- Belt tensioner added on the axis X

- All bearings are now 624ZZ: Miniaturization of the « Y Idler » to support a 624 ball bearing.

All resources are on our website, you will find more information in the instruction section.

All improvements are compatible with the Prusa i3 Rework 1.0

Enjoy!

BOM

3D printed parts

Extruder parts

- Some data about the springs

- Height 20mm

- Outer diameter 7.5mm

- Inner diameter 5mm

Note: This construction manual uses a “Trinity Labs Magma” hotend which is not in production anymore, recommended alternatives (especially for newbies) are the “E3D V6” or “J-Head Mk V”.

Smooth and threaded rods

- 2x Smooth rod Ø8×320 mm (for the Z-axis)

- 2x Smooth rod Ø8×350 mm (for the Y-axis)

- 2x Smooth rod Ø8×370 mm (for the X-axis)

- 2x Threaded rod M5x300 mm (these are replaced by lead screws / ACME rods in the new revision)

- 4x Threaded rod M10x210 mm

- 2x Threaded rod M10x380 mm

Mechanical parts

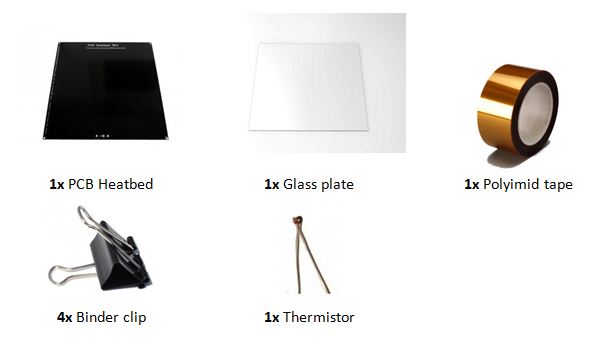

Heated bed

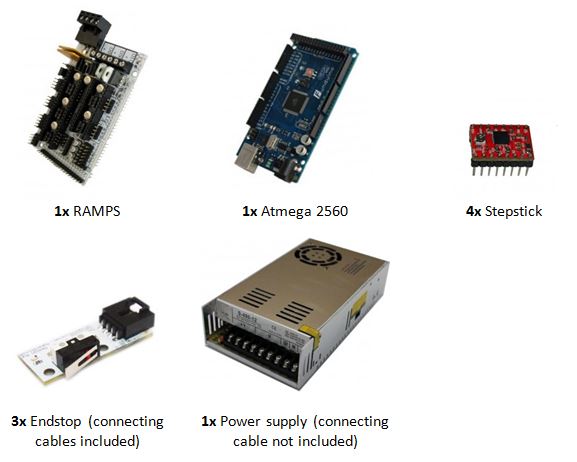

Electronics

Screws, nuts and washers

If using the SainSmart endstops then you will need 2 M3 flat head screws per endstop that uses the bottom 2 holes to attach it (example the X-Idler) as the SainSmart endstops has a bad design flaw that gives absolutely zero clearance for the two lower screws as the wiring harness is too close to the pcb and over laps some of the 2 bottom open holes (wiring harness points downward at a 90 degree angle). With these you can bend up the wiring harness, ever so slightly and be extremely cautious and gentle, to get the flat head M3 screw heads to go under the harness. Once they are under the harness proceed to attach with the nuts but remember the heads MUST come into the holes from the side with the wiring harness due to the mentioned lack of any clearance.

If you are having a hard time finding the M3x60mm screws you can use 1/8 inch toggle bolts and remove the screw in piece from the toggle side (easily comes out) and it fits perfectly on the extruder. Use springs and a washer and you are set though I did use a Dremel to remove the threads for 1/2 of the bolt.

Frame

- 1x Single frame

- 1x Heated bed mount

Note: These can be laser/waterjet cut from 6mm-thick aluminum. The DXF files are available on Github.

Download Prusa i3 Rework 1.5 @ Thingiverse

[#/3dprinter/prusai3_rework/onderdelen/prusai3_rework” ]