MendelMax firmware – Marlin met RAMPS board

Marlin met RAMPS board

MendelMax

Deze pagina beschrijft het backuppen, bijwerken of instellen van de software Marlin voor de 3D printer “MendelMax”, met behulp van de Arduino IDE.

Wat heb je nodig?

1) Arduino IDE

2) 3D Printer Firmware – Marlin geconfigureerd voor MendelMax

Backup maken

Firmware backup

Voordat je begint met het updaten van een (goed werkende) printer, is het verstandig om eerst een backup te maken van de firmware van de Prusa i3, onder het RAMPS bord zit een Arduino MEGA, en backup met avrdude.exe is te maken met het commando:

avrdude.exe -v -c stk500v2 -p m2560 -P COM4 -b 115200 -U flash:r:mendelmax.hex:i

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 |

avrdude: Version 6.0.1, compiled on Apr 15 2015 at 19:59:58 Copyright (c) 2000-2005 Brian Dean, http://www.bdmicro.com/ Copyright (c) 2007-2009 Joerg Wunsch System wide configuration file is "c:ArduinoIDEhardwaretoolsavrbin avrdude.conf" Using Port : COM4 Using Programmer : stk500v2 Overriding Baud Rate : 115200 AVR Part : ATmega2560 Chip Erase delay : 9000 us PAGEL : PD7 BS2 : PA0 RESET disposition : dedicated RETRY pulse : SCK serial program mode : yes parallel program mode : yes Timeout : 200 StabDelay : 100 CmdexeDelay : 25 SyncLoops : 32 ByteDelay : 0 PollIndex : 3 PollValue : 0x53 Memory Detail : Block Poll Page Polled Memory Type Mode Delay Size Indx Paged Size Size #Pages MinW MaxW ReadBack ----------- ---- ----- ----- ---- ------ ------ ---- ------ ----- ----- --------- eeprom 65 10 8 0 no 4096 8 0 9000 9000 0x00 0x00 flash 65 10 256 0 yes 262144 256 1024 4500 4500 0x00 0x00 lfuse 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00 hfuse 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00 efuse 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00 lock 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00 calibration 0 0 0 0 no 1 0 0 0 0 0x00 0x00 signature 0 0 0 0 no 3 0 0 0 0 0x00 0x00 Programmer Type : STK500V2 Description : Atmel STK500 Version 2.x firmware Programmer Model: AVRISP Hardware Version: 15 Firmware Version Master : 2.10 Vtarget : 0.0 V SCK period : 43.5 us avrdude: AVR device initialized and ready to accept instructions Reading | ################################################## | 100% 0.02s avrdude: Device signature = 0x1e9801 avrdude: safemode: lfuse reads as FF avrdude: safemode: hfuse reads as D8 avrdude: safemode: efuse reads as FF avrdude: reading flash memory: Reading | ################################################## | 100% 31.28s avrdude: writing output file "prusa.hex" avrdude: safemode: lfuse reads as FF avrdude: safemode: hfuse reads as D8 avrdude: safemode: efuse reads as FF avrdude: safemode: Fuses OK (H:FF, E:D8, L:FF) avrdude done. Thank you. c:ArduinoIDEhardwaretoolsavrbin> |

Of

avrdude.exe -v -c wiring -p m2560 -P COM4 -b 115200 -U flash:r:mendelmax.hex:i

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 |

avrdude: Version 6.0.1, compiled on Apr 15 2015 at 19:59:58 Copyright (c) 2000-2005 Brian Dean, http://www.bdmicro.com/ Copyright (c) 2007-2009 Joerg Wunsch System wide configuration file is "f:ArduinoIDEhardwaretoolsavrbinavrdude.conf" Using Port : COM12 Using Programmer : wiring Overriding Baud Rate : 115200 AVR Part : ATmega2560 Chip Erase delay : 9000 us PAGEL : PD7 BS2 : PA0 RESET disposition : dedicated RETRY pulse : SCK serial program mode : yes parallel program mode : yes Timeout : 200 StabDelay : 100 CmdexeDelay : 25 SyncLoops : 32 ByteDelay : 0 PollIndex : 3 PollValue : 0x53 Memory Detail : Block Poll Page Polled Memory Type Mode Delay Size Indx Paged Size Size #Pages MinW MaxW ReadBack ----------- ---- ----- ----- ---- ------ ------ ---- ------ ----- ----- --------- eeprom 65 10 8 0 no 4096 8 0 9000 9000 0x00 0x00 flash 65 10 256 0 yes 262144 256 1024 4500 4500 0x00 0x00 lfuse 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00 hfuse 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00 efuse 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00 lock 0 0 0 0 no 1 0 0 9000 9000 0x00 0x00 calibration 0 0 0 0 no 1 0 0 0 0 0x00 0x00 signature 0 0 0 0 no 3 0 0 0 0 0x00 0x00 Programmer Type : Wiring Description : Wiring Programmer Model: AVRISP Hardware Version: 15 Firmware Version Master : 2.10 Vtarget : 0.0 V SCK period : 43.5 us avrdude: AVR device initialized and ready to accept instructions Reading | ################################################## | 100% 0.03s avrdude: Device signature = 0x1e9801 avrdude: safemode: lfuse reads as 0 avrdude: safemode: hfuse reads as 0 avrdude: safemode: efuse reads as 0 avrdude: reading flash memory: Reading | ################################################## | 100% 34.01s avrdude: writing output file "prusa.hex" avrdude: safemode: lfuse reads as 0 avrdude: safemode: hfuse reads as 0 avrdude: safemode: efuse reads as 0 avrdude: safemode: Fuses OK (H:00, E:00, L:00) avrdude done. Thank you. |

Ps. avrdude is te vinden in: [Arduino IDE]\hardware\tools\avrbin

(eventueel avrdude.conf uit [ArduinoIDE]\hardware\tools\avr\etc ook hierheen kopiëren)

Installeren van Marlin

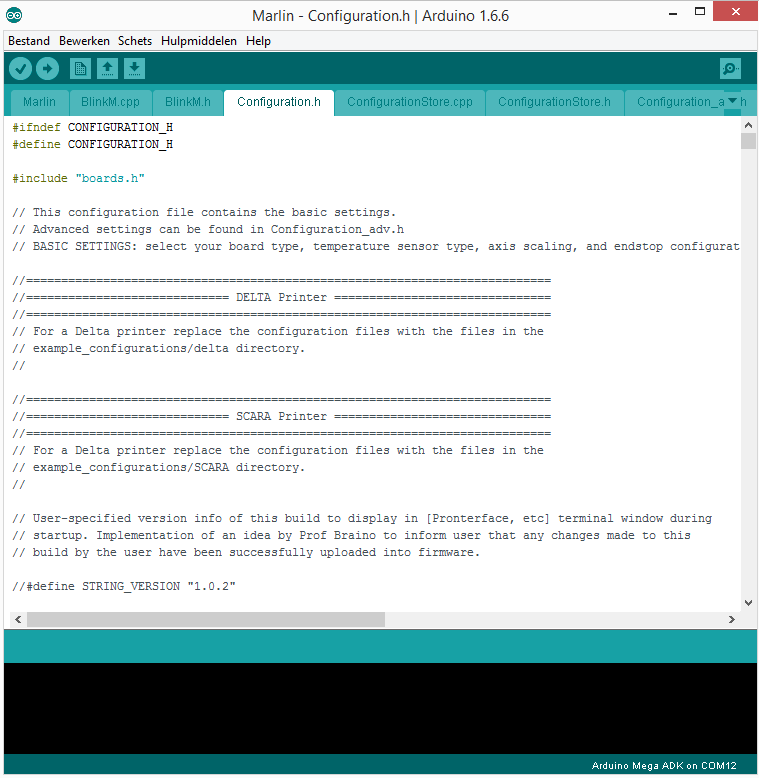

Nadat je ArduinoIDE hebt geïnstalleerd installeer je de “Marlin” folder vanuit het archief naar Arduino IDE

Start de Firmware op door op Marlin.ino te dubbelklikken, ArduinoIDE wordt dan opgestart, daarin zie je heel veel TAB’s en venstertjes openstaan:

Marlin configureren voor de MendelMax

Deze download is al geconfigureerd voor de MendelMax 1 / 1.5 / 2, op Github staat:

NOTE: This is the latest version of Marlin, pre-configured for the MendelMax printer kits

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200 201 202 203 |

#ifndef __CONFIGURATION_H #define __CONFIGURATION_H // This configurtion file contains the basic settings. // Advanced settings can be found in Configuration_adv.h // BASIC SETTINGS: select your board type, temperature sensor type, axis scaling, and endstop configuration //User specified version info of THIS file to display in [Pronterface, etc] terminal window during startup. //Implementation of an idea by Prof Braino to inform user that any changes made //to THIS file by the user have been successfully uploaded into firmware. #define STRING_VERSION_CONFIG_H "2012-02-11" //Personal revision number for changes to THIS file. #define STRING_CONFIG_H_AUTHOR "Maxbots" //Who made the changes. // This determines the communication speed of the printer #define BAUDRATE 250000 //#define BAUDRATE 115200 //// The following define selects which electronics board you have. Please choose the one that matches your setup // MEGA/RAMPS up to 1.2 = 3, // RAMPS 1.3 = 33 // Gen6 = 5, // Sanguinololu 1.2 and above = 62 // Ultimaker = 7, // Teensylu = 8, // Gen3+ =9 #define MOTHERBOARD 33 //=========================================================================== //=============================Thermal Settings ============================ //=========================================================================== //// Temperature sensor settings: // -2 is thermocouple with MAX6675 (only for sensor 0) // -1 is thermocouple with AD595 // 0 is not used // 1 is 100k thermistor // 2 is 200k thermistor // 3 is mendel-parts thermistor // 4 is 10k thermistor !! do not use it for a hotend. It gives bad resolution at high temp. !! // 5 is ParCan supplied 104GT-2 100K // 6 is EPCOS 100k // 7 is 100k Honeywell thermistor 135-104LAG-J01 #define TEMP_SENSOR_0 1 #define TEMP_SENSOR_1 0 #define TEMP_SENSOR_2 0 #define TEMP_SENSOR_BED 1 // Actual temperature must be close to target for this long before M109 returns success #define TEMP_RESIDENCY_TIME 30 // (seconds) #define TEMP_HYSTERESIS 3 // (C°) range of +/- temperatures considered "close" to the target one // The minimal temperature defines the temperature below which the heater will not be enabled It is used // to check that the wiring to the thermistor is not broken. // Otherwise this would lead to the heater being powered on all the time. #define HEATER_0_MINTEMP 5 #define HEATER_1_MINTEMP 5 #define HEATER_2_MINTEMP 5 #define BED_MINTEMP 5 // When temperature exceeds max temp, your heater will be switched off. // This feature exists to protect your hotend from overheating accidentally, but *NOT* from thermistor short/failure! // You should use MINTEMP for thermistor short/failure protection. #define HEATER_0_MAXTEMP 275 #define HEATER_1_MAXTEMP 275 #define HEATER_2_MAXTEMP 275 #define BED_MAXTEMP 150 // PID settings: // Comment the following line to disable PID and enable bang-bang. //#define PIDTEMP #define PID_MAX 255 // limits current to nozzle; 255=full current #ifdef PIDTEMP //#define PID_DEBUG // Sends debug data to the serial port. //#define PID_OPENLOOP 1 // Puts PID in open loop. M104 sets the output power in % #define PID_INTEGRAL_DRIVE_MAX 255 //limit for the integral term #define K1 0.95 //smoothing factor withing the PID #define PID_dT 0.128 //sampling period of the PID // If you are using a preconfigured hotend then you can use one of the value sets by uncommenting it // Ultimaker // #define DEFAULT_Kp 22.2 // #define DEFAULT_Ki (1.25*PID_dT) // #define DEFAULT_Kd (99/PID_dT) // Makergear #define DEFAULT_Kp 7.0 #define DEFAULT_Ki 0.1 #define DEFAULT_Kd 12 // Mendel Parts V9 on 12V // #define DEFAULT_Kp 63.0 // #define DEFAULT_Ki (2.25*PID_dT) // #define DEFAULT_Kd (440/PID_dT) #endif // PIDTEMP //this prevents dangerous Extruder moves, i.e. if the temperature is under the limit //can be software-disabled for whatever purposes by #define PREVENT_DANGEROUS_EXTRUDE #define EXTRUDE_MINTEMP 170 #define EXTRUDE_MAXLENGTH (X_MAX_LENGTH+Y_MAX_LENGTH) //prevent extrusion of very large distances. //=========================================================================== //=============================Mechanical Settings=========================== //=========================================================================== // Endstop Settings #define ENDSTOPPULLUPS // Comment this out (using // at the start of the line) to disable the endstop pullup resistors // The pullups are needed if you directly connect a mechanical endswitch between the signal and ground pins. const bool X_ENDSTOPS_INVERTING = true; // set to true to invert the logic of the endstops. const bool Y_ENDSTOPS_INVERTING = true; // set to true to invert the logic of the endstops. const bool Z_ENDSTOPS_INVERTING = true; // set to true to invert the logic of the endstops. // For Inverting Stepper Enable Pins (Active Low) use 0, Non Inverting (Active High) use 1 #define X_ENABLE_ON 0 #define Y_ENABLE_ON 0 #define Z_ENABLE_ON 0 #define E_ENABLE_ON 0 // For all extruders // Disables axis when it's not being used. #define DISABLE_X false #define DISABLE_Y false #define DISABLE_Z true #define DISABLE_E false // For all extruders #define INVERT_X_DIR true // for Mendel set to false, for Orca set to true #define INVERT_Y_DIR false // for Mendel set to true, for Orca set to false #define INVERT_Z_DIR false // for Mendel set to false, for Orca set to true #define INVERT_E0_DIR true // for direct drive extruder v9 set to true, for geared extruder set to false #define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false #define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false // ENDSTOP SETTINGS: // Sets direction of endstops when homing; 1=MAX, -1=MIN #define X_HOME_DIR -1 #define Y_HOME_DIR -1 #define Z_HOME_DIR -1 #define min_software_endstops false //If true, axis won't move to coordinates less than zero. #define max_software_endstops false //If true, axis won't move to coordinates greater than the defined lengths below. #define X_MAX_LENGTH 215 #define Y_MAX_LENGTH 235 #define Z_MAX_LENGTH 170 //// MOVEMENT SETTINGS #define NUM_AXIS 4 // The axis order in all axis related arrays is X, Y, Z, E #define HOMING_FEEDRATE {50*60, 50*60, 4*60, 0} // set the homing speeds (mm/min) // default settings #define DEFAULT_AXIS_STEPS_PER_UNIT {44.444444444,44.444444444,2015.748031496063,1384} // default steps per unit for ultimaker #define DEFAULT_MAX_FEEDRATE {500, 500, 5, 45} // (mm/sec) #define DEFAULT_MAX_ACCELERATION {9000,9000,100,10000} // X, Y, Z, E maximum start speed for accelerated moves. E default values are good for skeinforge 40+, for older versions raise them a lot. #define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves #define DEFAULT_RETRACT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for r retracts // #define DEFAULT_XYJERK 20.0 // (mm/sec) #define DEFAULT_ZJERK 0.4 // (mm/sec) //=========================================================================== //=============================Additional Features=========================== //=========================================================================== // EEPROM // the microcontroller can store settings in the EEPROM, e.g. max velocity... // M500 - stores paramters in EEPROM // M501 - reads parameters from EEPROM (if you need reset them after you changed them temporarily). // M502 - reverts to the default "factory settings". You still need to store them in EEPROM afterwards if you want to. //define this to enable eeprom support //#define EEPROM_SETTINGS //to disable EEPROM Serial responses and decrease program space by ~1700 byte: comment this out: // please keep turned on if you can. //#define EEPROM_CHITCHAT //LCD and SD support //#define ULTRA_LCD //general lcd support, also 16x2 #define SDSUPPORT // Enable SD Card Support in Hardware Console //#define ULTIPANEL #ifdef ULTIPANEL //#define NEWPANEL //enable this if you have a click-encoder panel #define SDSUPPORT #define ULTRA_LCD #define LCD_WIDTH 20 #define LCD_HEIGHT 4 #else //no panel but just lcd #ifdef ULTRA_LCD #define LCD_WIDTH 16 #define LCD_HEIGHT 2 #endif #endif // M240 Triggers a camera by emulating a Canon RC-1 Remote // Data from: http://www.doc-diy.net/photo/rc-1_hacked/ // #define PHOTOGRAPH_PIN 23 #include "Configuration_adv.h" #include "thermistortables.h" #endif //__CONFIGURATION_H |

MendelMax Pro marlin configuration.h

|

1 2 3 4 5 6 7 8 9 10 11 12 13 14 15 16 17 18 19 20 21 22 23 24 25 26 27 28 29 30 31 32 33 34 35 36 37 38 39 40 41 42 43 44 45 46 47 48 49 50 51 52 53 54 55 56 57 58 59 60 61 62 63 64 65 66 67 68 69 70 71 72 73 74 75 76 77 78 79 80 81 82 83 84 85 86 87 88 89 90 91 92 93 94 95 96 97 98 99 100 101 102 103 104 105 106 107 108 109 110 111 112 113 114 115 116 117 118 119 120 121 122 123 124 125 126 127 128 129 130 131 132 133 134 135 136 137 138 139 140 141 142 143 144 145 146 147 148 149 150 151 152 153 154 155 156 157 158 159 160 161 162 163 164 165 166 167 168 169 170 171 172 173 174 175 176 177 178 179 180 181 182 183 184 185 186 187 188 189 190 191 192 193 194 195 196 197 198 199 200 201 202 203 204 205 206 207 208 209 210 211 212 213 214 215 216 217 218 219 220 221 222 223 224 225 226 227 228 229 230 231 232 233 234 235 236 237 238 239 240 241 242 243 244 245 246 247 248 249 250 251 252 253 254 255 256 257 258 259 260 261 262 263 264 265 266 267 268 269 270 271 272 273 274 275 276 277 278 279 280 281 282 283 284 |

#ifndef CONFIGURATION_H #define CONFIGURATION_H // This configurtion file contains the basic settings. // Advanced settings can be found in Configuration_adv.h // BASIC SETTINGS: select your board type, temperature sensor type, axis scaling, and endstop configuration //User specified version info of THIS file to display in [Pronterface, etc] terminal window during startup. //Implementation of an idea by Prof Braino to inform user that any changes made //to THIS file by the user have been successfully uploaded into firmware. #define STRING_VERSION_CONFIG_H "2012-09-07" //Personal revision number for changes to THIS file. #define STRING_CONFIG_H_AUTHOR "EZRA" //Who made the changes. // This determines the communication speed of the printer #define BAUDRATE 250000 //#define BAUDRATE 115200 //// The following define selects which electronics board you have. Please choose the one that matches your setup // Gen7 custom (Alfons3 Version) = 10 "https://github.com/Alfons3/Generation_7_Electronics" // Gen7 v1.1, v1.2 = 11 // Gen7 v1.3 = 12 // Gen7 v1.4 = 13 // MEGA/RAMPS up to 1.2 = 3 // RAMPS 1.3 = 33 (Power outputs: Extruder, Bed, Fan) // RAMPS 1.3 = 34 (Power outputs: Extruder0, Extruder1, Bed) // Gen6 = 5 // Gen6 deluxe = 51 // Sanguinololu 1.2 and above = 62 // Melzi = 63 // Ultimaker = 7 // Teensylu = 8 // Gen3+ =9 #ifndef MOTHERBOARD #define MOTHERBOARD 33 #endif //=========================================================================== //=============================Thermal Settings ============================ //=========================================================================== // //--NORMAL IS 4.7kohm PULLUP!-- 1kohm pullup can be used on hotend sensor, using correct resistor and table // //// Temperature sensor settings: // -2 is thermocouple with MAX6675 (only for sensor 0) // -1 is thermocouple with AD595 // 0 is not used // 1 is 100k thermistor - best choice for EPCOS 100k (4.7k pullup) // 2 is 200k thermistor - ATC Semitec 204GT-2 (4.7k pullup) // 3 is mendel-parts thermistor (4.7k pullup) // 4 is 10k thermistor !! do not use it for a hotend. It gives bad resolution at high temp. !! // 5 is 100K thermistor - ATC Semitec 104GT-2 (Used in ParCan) (4.7k pullup) // 6 is 100k EPCOS - Not as accurate as table 1 (created using a fluke thermocouple) (4.7k pullup) // 7 is 100k Honeywell thermistor 135-104LAG-J01 (4.7k pullup) // // 1k ohm pullup tables - This is not normal, you would have to have changed out your 4.7k for 1k // (but gives greater accuracy and more stable PID) // 51 is 100k thermistor - EPCOS (1k pullup) // 52 is 200k thermistor - ATC Semitec 204GT-2 (1k pullup) // 55 is 100k thermistor - ATC Semitec 104GT-2 (Used in ParCan) (1k pullup) #define TEMP_SENSOR_0 1 #define TEMP_SENSOR_1 0 #define TEMP_SENSOR_2 0 #define TEMP_SENSOR_BED 60 // Actual temperature must be close to target for this long before M109 returns success #define TEMP_RESIDENCY_TIME 3 // (seconds) #define TEMP_HYSTERESIS 5 // (degC) range of +/- temperatures considered "close" to the target one #define TEMP_WINDOW 1 // (degC) Window around target to start the recidency timer x degC early. // The minimal temperature defines the temperature below which the heater will not be enabled It is used // to check that the wiring to the thermistor is not broken. // Otherwise this would lead to the heater being powered on all the time. #define HEATER_0_MINTEMP 5 #define HEATER_1_MINTEMP 5 #define HEATER_2_MINTEMP 5 #define BED_MINTEMP 5 // When temperature exceeds max temp, your heater will be switched off. // This feature exists to protect your hotend from overheating accidentally, but *NOT* from thermistor short/failure! // You should use MINTEMP for thermistor short/failure protection. #define HEATER_0_MAXTEMP 245 #define HEATER_1_MAXTEMP 245 #define HEATER_2_MAXTEMP 245 #define BED_MAXTEMP 150 // PID settings: // Comment the following line to disable PID and enable bang-bang. #define PIDTEMP #define PID_MAX 255 // limits current to nozzle; 255=full current #ifdef PIDTEMP //#define PID_DEBUG // Sends debug data to the serial port. //#define PID_OPENLOOP 1 // Puts PID in open loop. M104 sets the output power in % #define PID_INTEGRAL_DRIVE_MAX 255 //limit for the integral term #define K1 0.95 //smoothing factor withing the PID #define PID_dT ((16.0 * 8.0)/(F_CPU / 64.0 / 256.0)) //sampling period of the // If you are using a preconfigured hotend then you can use one of the value sets by uncommenting it // Ultimaker // #define DEFAULT_Kp 22.2 // #define DEFAULT_Ki 1.08 // #define DEFAULT_Kd 114 //Makergear #define DEFAULT_Kp 7.0 #define DEFAULT_Ki 0.1 #define DEFAULT_Kd 12 // Mendel Parts V9 on 12V // #define DEFAULT_Kp 63.0 // #define DEFAULT_Ki 2.25 // #define DEFAULT_Kd 440 #endif // PIDTEMP //this prevents dangerous Extruder moves, i.e. if the temperature is under the limit //can be software-disabled for whatever purposes by #define PREVENT_DANGEROUS_EXTRUDE //if PREVENT_DANGEROUS_EXTRUDE is on, you can still disable (uncomment) very long bits of extrusion separately. #define PREVENT_LENGTHY_EXTRUDE #define EXTRUDE_MINTEMP 165 #define EXTRUDE_MAXLENGTH (X_MAX_LENGTH+Y_MAX_LENGTH) //prevent extrusion of very large distances. //=========================================================================== //=============================Mechanical Settings=========================== //=========================================================================== // Uncomment the following line to enable CoreXY kinematics // #define COREXY // corse Endstop Settings #define ENDSTOPPULLUPS // Comment this out (using // at the start of the line) to disable the endstop pullup resistors #ifndef ENDSTOPPULLUPS // fine Enstop settings: Individual Pullups. will be ignord if ENDSTOPPULLUPS is defined #define ENDSTOPPULLUP_XMAX #define ENDSTOPPULLUP_YMAX #define ENDSTOPPULLUP_ZMAX #define ENDSTOPPULLUP_XMIN #define ENDSTOPPULLUP_YMIN //#define ENDSTOPPULLUP_ZMIN #endif #ifdef ENDSTOPPULLUPS #define ENDSTOPPULLUP_XMAX #define ENDSTOPPULLUP_YMAX #define ENDSTOPPULLUP_ZMAX #define ENDSTOPPULLUP_XMIN #define ENDSTOPPULLUP_YMIN #define ENDSTOPPULLUP_ZMIN #endif // The pullups are needed if you directly connect a mechanical endswitch between the signal and ground pins. const bool X_ENDSTOPS_INVERTING = true; // set to true to invert the logic of the endstops. const bool Y_ENDSTOPS_INVERTING = true; // set to true to invert the logic of the endstops. const bool Z_ENDSTOPS_INVERTING = true; // set to true to invert the logic of the endstops. //#define DISABLE_MAX_ENDSTOPS // For Inverting Stepper Enable Pins (Active Low) use 0, Non Inverting (Active High) use 1 #define X_ENABLE_ON 0 #define Y_ENABLE_ON 0 #define Z_ENABLE_ON 0 #define E_ENABLE_ON 0 // For all extruders // Disables axis when it's not being used. #define DISABLE_X false #define DISABLE_Y false #define DISABLE_Z true #define DISABLE_E false // For all extruders #define INVERT_X_DIR true // for Mendel set to false, for Orca set to true #define INVERT_Y_DIR false // for Mendel set to true, for Orca set to false #define INVERT_Z_DIR true // for Mendel set to false, for Orca set to true #define INVERT_E0_DIR true // for direct drive extruder v9 set to true, for geared extruder set to false #define INVERT_E1_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false #define INVERT_E2_DIR false // for direct drive extruder v9 set to true, for geared extruder set to false // ENDSTOP SETTINGS: // Sets direction of endstops when homing; 1=MAX, -1=MIN #define X_HOME_DIR -1 #define Y_HOME_DIR -1 #define Z_HOME_DIR -1 #define min_software_endstops false //If true, axis won't move to coordinates less than HOME_POS. #define max_software_endstops false //If true, axis won't move to coordinates greater than the defined lengths below. // Travel limits after homing #define X_MAX_POS 205 #define X_MIN_POS 0 #define Y_MAX_POS 205 #define Y_MIN_POS 0 #define Z_MAX_POS 200 #define Z_MIN_POS 0 #define X_MAX_LENGTH (X_MAX_POS - X_MIN_POS) #define Y_MAX_LENGTH (Y_MAX_POS - Y_MIN_POS) #define Z_MAX_LENGTH (Z_MAX_POS - Z_MIN_POS) // The position of the homing switches. Use MAX_LENGTH * -0.5 if the center should be 0, 0, 0 #define X_HOME_POS 0 #define Y_HOME_POS 0 #define Z_HOME_POS 0 //// MOVEMENT SETTINGS #define NUM_AXIS 4 // The axis order in all axis related arrays is X, Y, Z, E #define HOMING_FEEDRATE {50*60, 50*60, 4*60, 0} // set the homing speeds (mm/min) // default settings #define DEFAULT_AXIS_STEPS_PER_UNIT {80,80,1600,1061.95} // default steps per unit for ultimaker #define DEFAULT_MAX_FEEDRATE {500, 500, 5, 200} // (mm/sec) #define DEFAULT_MAX_ACCELERATION {1500,1500,50,500} #define DEFAULT_ACCELERATION 3000 // X, Y, Z and E max acceleration in mm/s^2 for printing moves #define DEFAULT_RETRACT_ACCELERATION 1000 // X, Y, Z and E max acceleration in mm/s^2 for r retracts #define DEFAULT_XYJERK 20.0 // (mm/sec) #define DEFAULT_ZJERK 1.5 // (mm/sec) #define DEFAULT_EJERK 2.5 // (mm/sec) //=========================================================================== //=============================Additional Features=========================== //=========================================================================== // EEPROM // the microcontroller can store settings in the EEPROM, e.g. max velocity... // M500 - stores paramters in EEPROM // M501 - reads parameters from EEPROM (if you need reset them after you changed them temporarily). // M502 - reverts to the default "factory settings". You still need to store them in EEPROM afterwards if you want to. //define this to enable eeprom support //#define EEPROM_SETTINGS //to disable EEPROM Serial responses and decrease program space by ~1700 byte: comment this out: // please keep turned on if you can. //#define EEPROM_CHITCHAT //LCD and SD support //#define ULTRA_LCD //general lcd support, also 16x2 //#define SDSUPPORT // Enable SD Card Support in Hardware Console #define ULTIMAKERCONTROLLER //as available from the ultimaker online store. //#define ULTIPANEL //the ultipanel as on thingiverse #ifdef ULTIMAKERCONTROLLER //automatic expansion #define ULTIPANEL #define NEWPANEL #endif #ifdef ULTIPANEL #define NEWPANEL //enable this if you have a click-encoder panel #define SDSUPPORT #define ULTRA_LCD #define LCD_WIDTH 20 #define LCD_HEIGHT 4 // Preheat Constants #define PLA_PREHEAT_HOTEND_TEMP 180 #define PLA_PREHEAT_HPB_TEMP 70 #define PLA_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255 #define ABS_PREHEAT_HOTEND_TEMP 240 #define ABS_PREHEAT_HPB_TEMP 100 #define ABS_PREHEAT_FAN_SPEED 255 // Insert Value between 0 and 255 #else //no panel but just lcd #ifdef ULTRA_LCD #define LCD_WIDTH 16 #define LCD_HEIGHT 2 #endif #endif // Increase the FAN pwm frequency. Removes the PWM noise but increases heating in the FET/Arduino #define FAST_PWM_FAN // M240 Triggers a camera by emulating a Canon RC-1 Remote // Data from: http://www.doc-diy.net/photo/rc-1_hacked/ // #define PHOTOGRAPH_PIN 23 #include "Configuration_adv.h" #include "thermistortables.h" #endif //__CONFIGURATION_H |

0.1mm tweak

Hier staat een stukje om goed 0.1mm te printen, ter info:

I was having trouble printing some 0.1mm stuff and what I did was copy the feedrate, acceleration and jerk settings from the (original?) Marlin config, and changed the layer height in the Slic3r config to 0.1mm. I left everything else the same.

[#/3dprinter/mendelmax/mendelmax1/firmware” ]