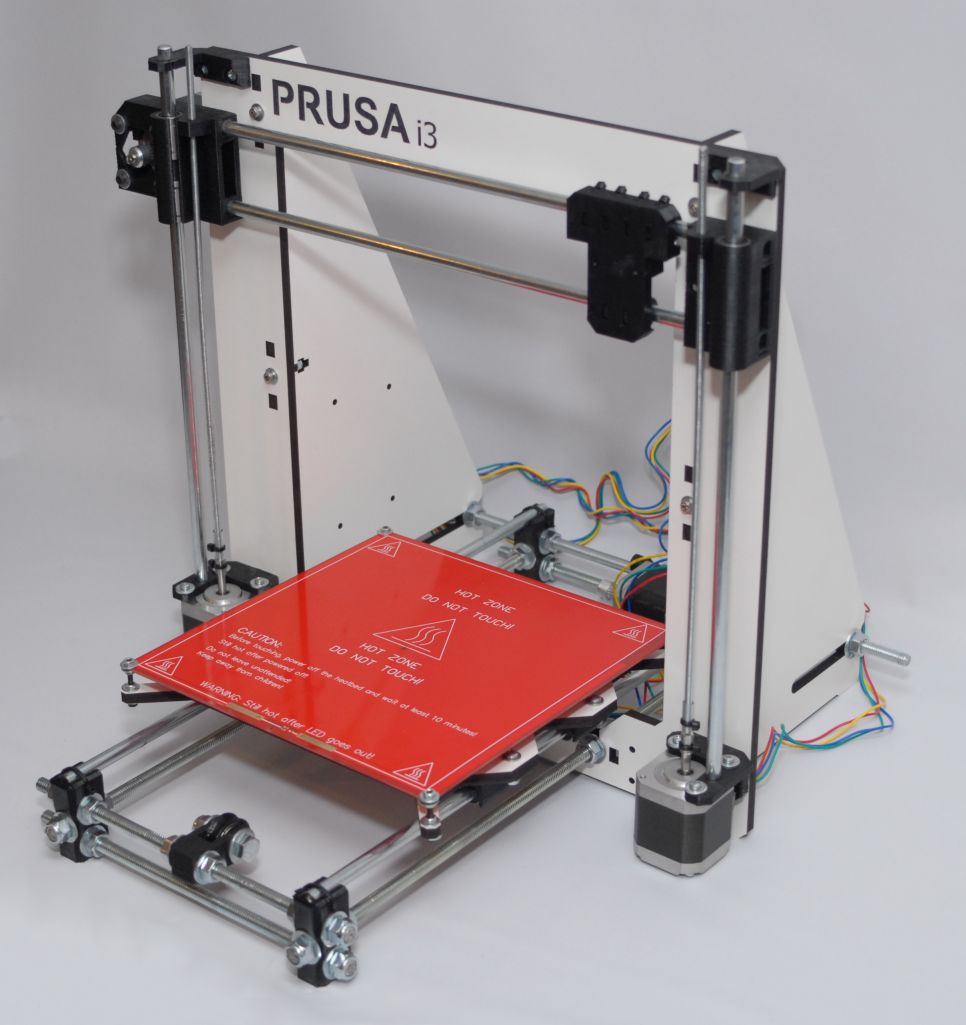

Prusa i3 – Informatie en onderdelen

3D Printer

Prusa i3

Informatie (ENG):

The Prusa i3 is a Cartesian style Open Source RepRap 3D printer designed by Josef Prusa. The design of the Prusa i3 did not emerge out of the vacuum, it is actually – as its name indicates – the third iteration of a basic design by Josef Prusa, and as such it was preceded by the Prusa i2.

However, this page is not concerned with what preceded the Prusa i3, but rather with what followed it!

The design of the Prusa i3 can be described by various subjective qualities (e.g. “clean”, “simple”, “good-looking”, etc) but it is due to some very objective factors that the Prusa i3 has spawned a large number of variants worldwide:

- The Prusa i3 design is licensed under the GPL.

- The Prusa i3 design and assembly process are properly documented.

- The Prusa i3 is a low cost design.

The Prusa i3 variants use various different materials for the frame, and have specific design objectives in relation to the original Prusa i3. These various objectives can be one or a combination of:

- a reduction in cost.

- a reduction in the total number of parts.

- a reduction in the number of printed parts, or their replacement altogether with parts resulting from a different production process (e.g. laser-cutting).

- a reduction in the time required for assembly or adjustments.

- increased rigidity of the frame.

- increased robustness of the parts.

- changes in the “looks” for simple aesthetic reasons.

- other possible optimizations.

Specifications

| Single Sheet Frame | Box Frame | |

|---|---|---|

| Plastic Parts (exc. Extruder) | 26 | 29 |

| Non Printed Parts (approx.) | 337 | 293 |

| Cost (USD) | $300-1000 | $300-$800 |

| Controller Electronics | Almost all RepRap | Almost all RepRap |

| Printing Size (mm) | 200 x 200 x 200 | 200 x 200 x 270 |

| Motors | 5 x NEMA 17 Stepper | 5 x NEMA 17 Stepper |

| Frame Material | 6mm Aluminium, Wood | 12mm Wood |

| Frame Manufacture | Laser Cutter, CNC, Water Jet | Basic Woodwork Tools |

| Pro | Easy assembly | Rigid XZ to Y Connection |

| Con | Specialised Tools | Looks less professional? |

Main improvements

The following is a list of the main improvements made upon the Prusa Mendel Iteration 2

- Enhanced frame rigidity (prevents x-axis backlash)

- Easy assembly

- Parametric files for multiple sizes/bearings or bushings

Variants

The release of the Prusa i3 under the GPL license and numerous other factors (its low cost, minimal BOM, simple assembly and calibration procedures, more than adequate documentation, etc) have encouraged the further development of a growing number of Prusa i3 “variants” worldwide, with different parts, different materials and different assembly processes, but which altogether adhere to the general looks, component assembly, dimensions and functionality of the original Prusa i3.

See the page Prusa_i3_Variants for an attempt to list the Prusa i3 Open Source variants along with their differences / improvements and “genetic lineage”.

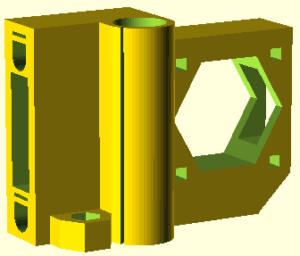

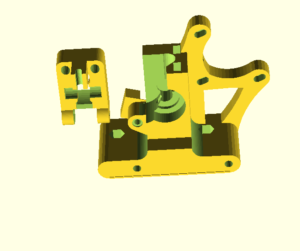

Printed Parts

OpenSCAD files for the printed parts are available on the Github repository.

To compile the parts and render STL files, copy configuration.scad.dist to configuration.scad, and customize by editing values.

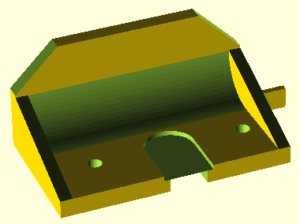

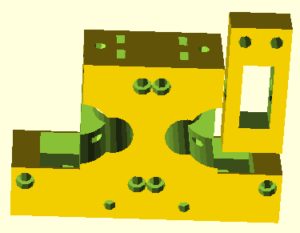

Frame type

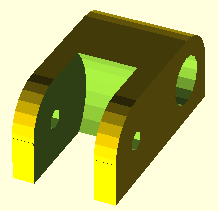

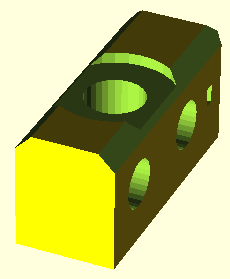

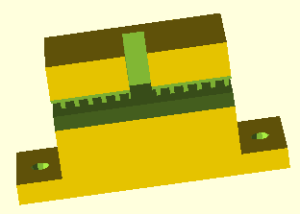

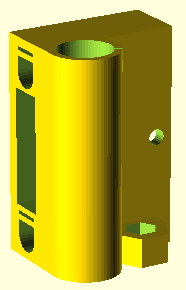

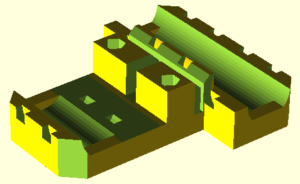

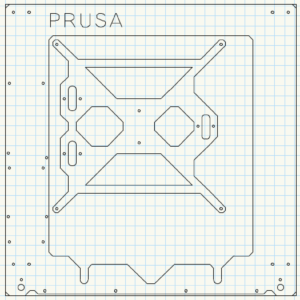

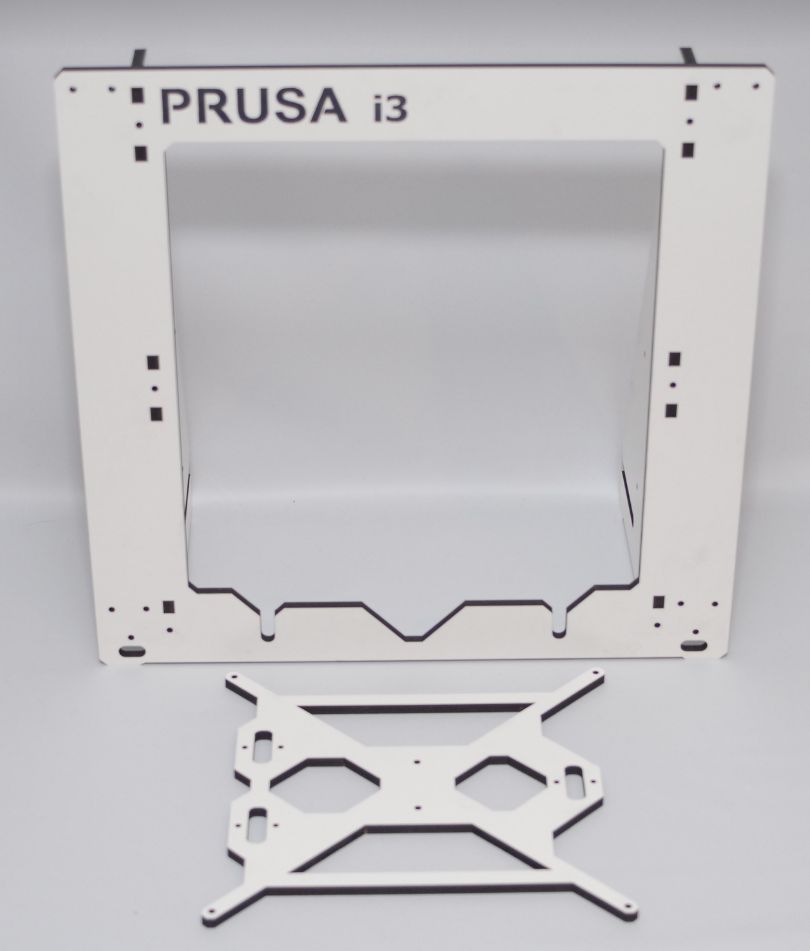

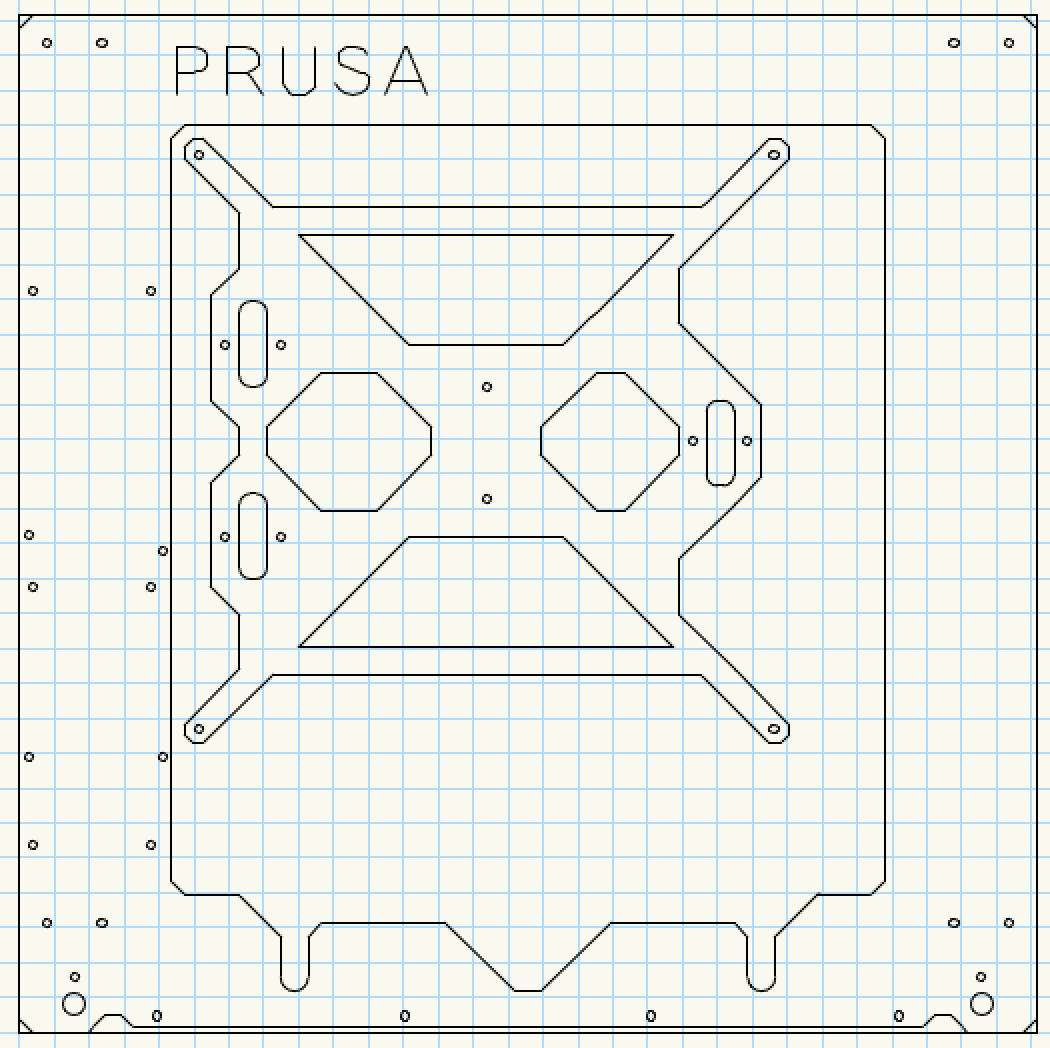

Most major Prusa i3 Frame Styles fall into two categories: the Single Sheet Frame, and the Box Style Frame.

The Single Sheet Frame is designed to be manufactured through the use of a Laser cutter, WaterJet, or CNC Mill / Router Table. There are two current development tracks within the Single Sheet Frame, an Aluminium frame style, and a gusseted Wood frame style. Both are designed to support 6mm or thicker framing material. Both the EiNSTeiN variant and the i3 Rework designs use single sheet aluminum frames, as do most kits. The Box Style Frame, on the other hand, is designed to be easily manufactured at home with basic woodworking tools. The Y-axis for both frame styles is similar to that of the older Prusa Mendel Iteration 2.

Electronics

Stepper Motors

The Prusa i3 uses, including the extruder, 5 NEMA17 stepper motors. Two of these motors, the Z axis motors, are connected to the same stepper driver of the electronics. If using Wade’s Extruder, its stepper motor needs a minimum holding torque of 40Ncm (0.4Nm). More information can be found on the Stepper Motor page.

Controller Electronics

About any RepRap controller works for the Prusa i3. Required features: 4 stepper drivers, 1 thermistor input and 1 heater output for the extruder and optionally another thermistor/heater pair for the heated bed. Choosing the best one for your printer is mostly a matter of taste.

BOM

BotBuilder Prusa i3 Bill of Materials

Notes: This is the exact list of what we use in our assembly classes, and should get anyone building an i3 using RAMPS to 99% completion. Some things may be slightly different because of the parts we’re using. For threaded rods and hardware we use all stainless steel. For smooth rods we use all chromed / hardened rods. All bolts are socket cap type. If you’re ordering nuts and bolts, order some spares. These counts assume that your single plate frame is tapped, not drilled. If it’s drilled you’ll need a lot more M3 nuts. This build assumes you’re using the sgraber i3ext for the extruder.

| Basic Parts | qty | Notes |

|---|---|---|

| Single sheet aluminum frame | 1 | |

| Printed parts | 26 | Including endstop brackets |

| Hotend - J-head MKV | 1 | |

| Heated build platform - MK2A | 1 | |

| Heated build platform glass - borosilicate | 1 | |

| Electronics | ||

| Arduino mega 2560 | 1 | |

| RAMPS 1.4 shield | 1 | |

| Pololu stepper drivers | 5 | |

| Endstop switches | 3 | |

| Power Supply - 12v 30A | 1 | |

| Four conductor 14AWG wire (meters) | 1 | |

| Stepper motors - Kysan 1124090 | 5 | |

| Hardware | ||

| Z-axis | ||

| M5 threaded - length 300mm | 2 | |

| M8 smooth - length 320mm | 2 | |

| X-axis | ||

| M8 smooth - length 370mm | 2 | |

| M8 smooth - length 20mm | 1 | Extruder idler axle |

| M5 threaded - length 69mm | 1 | Extruder drive shaft |

| Y-axis | ||

| M8 threaded - length 205mm | 4 | |

| M10 threaded - length 380mm | 2 | |

| M8 smooth - length 350mm | 2 | |

| M10 washer | 8 | |

| M10 nut | 12 | |

| M8 washer | 22 | |

| M8 nut | 22 | |

| M10 fender washer | 4 | |

| M3X10 | 23 | |

| M3x16 | 6 | |

| M3x18 | 5 | |

| M3x25 | 1 | |

| M3 locking nut | 13 | |

| M5 nut | 2 | |

| M5 locking nut | 1 | |

| M5 washer | 2 | |

| M3 nut | 6 | |

| M3x40 | 2 | |

| M3 washers | 2 | |

| M3 x 30 | 6 | |

| Bearings | ||

| LM8UU | 10 | |

| 623zz | 2 | Can also use 624's, but will need to print appropriate belt guides. |

| 625zz | 2 | |

| 608zz | 1 | |

| Misc | ||

| Extruder springs | 2 | We use springs from Ikea Pressa clothespins. |

| Nylon spacers | 4 | You need at least 20mm if you're using prusa3-vanilla parts - our X-motor-end is slightly lengthened to avoid this issue. |

| MK7 filament drive gear - 5mm shaft | 1 | |

| 40mm 12v fan for extruder | 1 | |

| Wires | 1 | You'll need a set of wires for the motors, endstops, thermistors, etc. |

| 100k Thermistor | 2 | Some electronic sets ship with them, as do some HBP kits. Some hotends come with them, etc. |

| GT2 Belts | 2 | You need 2 meters |

| GT2 Pulleys | 2 | |

| Zip ties | tons | 4" and 6" |

| Power cable | 1 | To go from PSU to wall outlet |

| USB cable | 1 | To go from PC to Arduino |

| Wire loom or 'techflex' cable mesh | 2 | (meters) |

| Heat shrink | ||

| Binder clips | 4 |

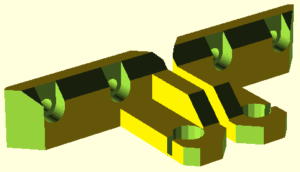

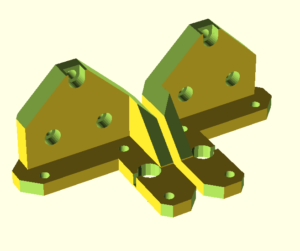

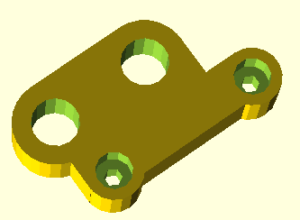

The following is a list of what needs to be printed:

Rapid Prototype Parts

| Description | Qty | Image |

| RP Parts | located in Prusa/single_plate folder | |

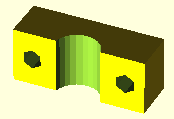

| z-axis-top.scad | 1 | |

| z-axis-bottom.scad | 1 | |

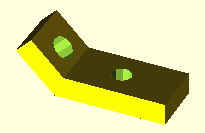

| y-motor.scad | 1 | |

| y-idler.scad | 1 | |

| y-corners.scad (M10 x 1 M8 x 2 holes) | 4 | |

| y-belt-holder.scad | 1 | |

| x-end-motor.scad | 1 | |

| x-end-idler.scad | 1 | |

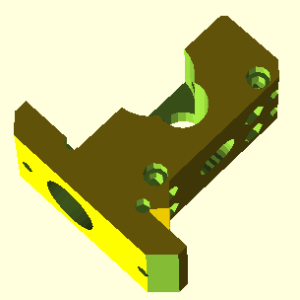

| x-carriage.scad | 1 | |

| magnetic-holder.scad (used for hall effect sensors / endstops) | 2 | |

| fan-mount.scad | 2 | |

| belt-guide.scad (suit 623 bearing) | 4 | |

| Extruder options | not complete documentation at this stage | |

| gregs-wade.scad (in box_frame/extras folder) | 1 (???) | |

| greg-adapter.scad (in mini/extruder/greg-wade folder) | 1 (???) | |

| dual-extruder.scad (deprecated – experimental) | 1 (???) | |

| compact-extruder.scad (experimental – likely to be replaced by nema17 extruder) | 1 (???) | |

| Single-Frame i3 | Aluminium 6mm plate 370mm x 370mm | |

| Prusa3ALU-FREZOVANY-v4.dxf | 1 |

Frame

Download Prusa i3 @ Github

Download Prusa i3 vanilla @ Github

[#/3dprinter/prusai3/onderdelen/prusai3″ ]